Diagram of Biofuels Being Processed — Complete Process Flow Guide (PFD/BFD)

Written by Admin | Nov 20, 2025

What a Biofuel Process Flow Diagram Shows (PFD vs. BFD vs. P&ID)

A block flow diagram (BFD) is the 10,000-foot view—just a handful of rectangles and arrows to show major steps like pretreatment → conversion → upgrading. A process flow diagram (PFD) zooms in on the real process: it shows the main equipment (reactors, distillation, heat exchangers), numbered streams, and mass/energy balance data that let engineers size units and heat recovery. A piping & instrumentation diagram (P&ID) goes deeper: every valve, instrument tag, control loop, and safety interlock that makes the plant run and stay safe. In short: BFD tells the story; PFD proves feasibility; P&ID enables construction and operations.

Symbols, Legends, and How to Read the Diagram

PFD/P&ID symbols are standardized so different teams can read the same “language.” Pumps, compressors, columns, vessels, and heat exchangers have conventional icons, and instrumentation bubbles follow ANSI/ISA-5.1 tag rules (e.g., FT-101 for a flow transmitter). Always start with the legend, trace streams by their IDs, then check the accompanying stream table for T/P, flow, and composition. On a P&ID, note control valves, relief paths, and alarms—those hint at hazards and operating limits.

Plain-language clarifications (added):

- Hydrotreating: Uses hydrogen to remove oxygen/impurities in bio-oils, producing cleaner hydrocarbons.

- Isomerization: Rearranges molecules to improve cold-flow properties (critical for jet/diesel).

- Saccharification: Enzyme/acid step that breaks starch/cellulose into fermentable sugars.

- Thin stillage: Liquid from ethanol distillation; commonly recycled or evaporated to make syrup.

Typical Inputs, Outputs, and Recirculation Loops

Across biofuel plants you’ll spot patterns: inputs (feedstock, make-up chemicals, steam, cooling water, power), outputs (fuel product, co-products like glycerol or DDGS, CO₂, wastewater), and loops (recycled alcohol in biodiesel; thin stillage recycle in ethanol; hot utility recovery via exchangers). Heat integration—preheating cold feeds with hot effluents—often shapes the PFD just as much as chemistry does.

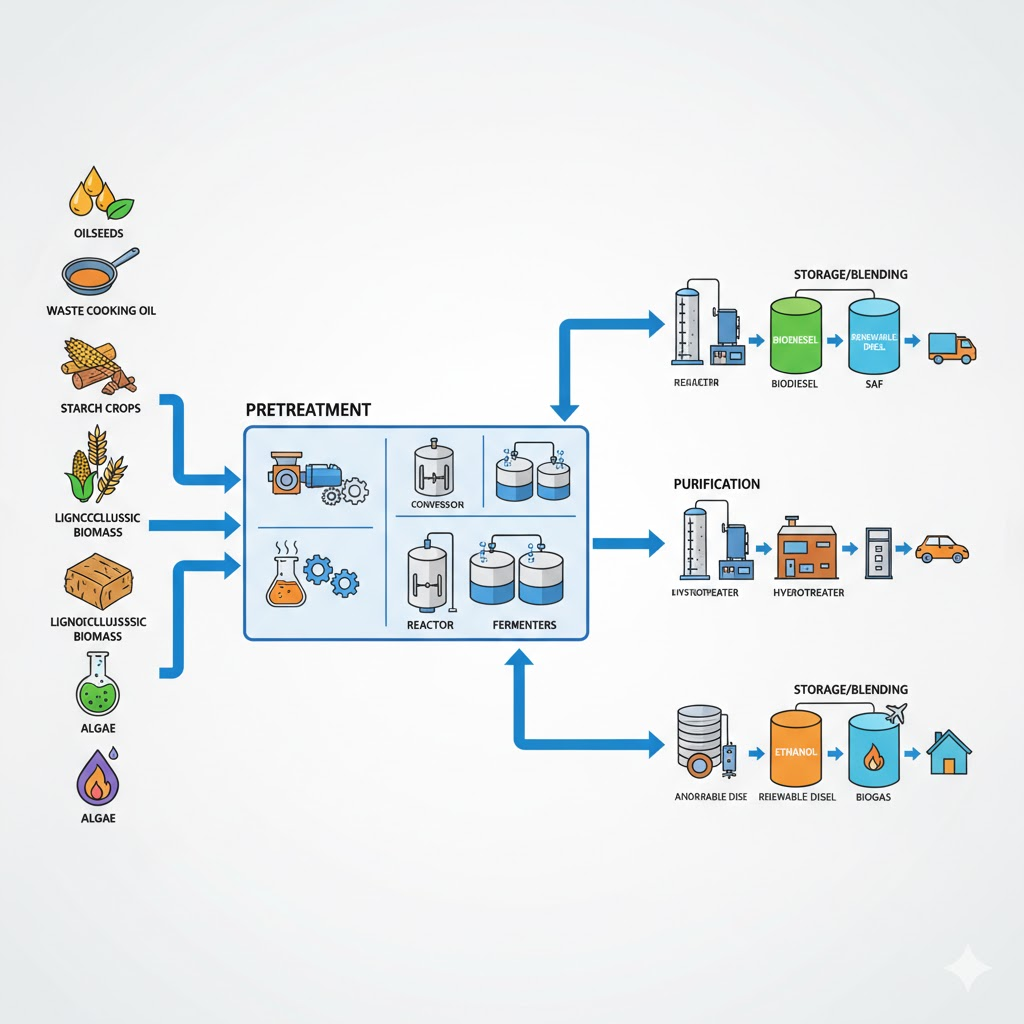

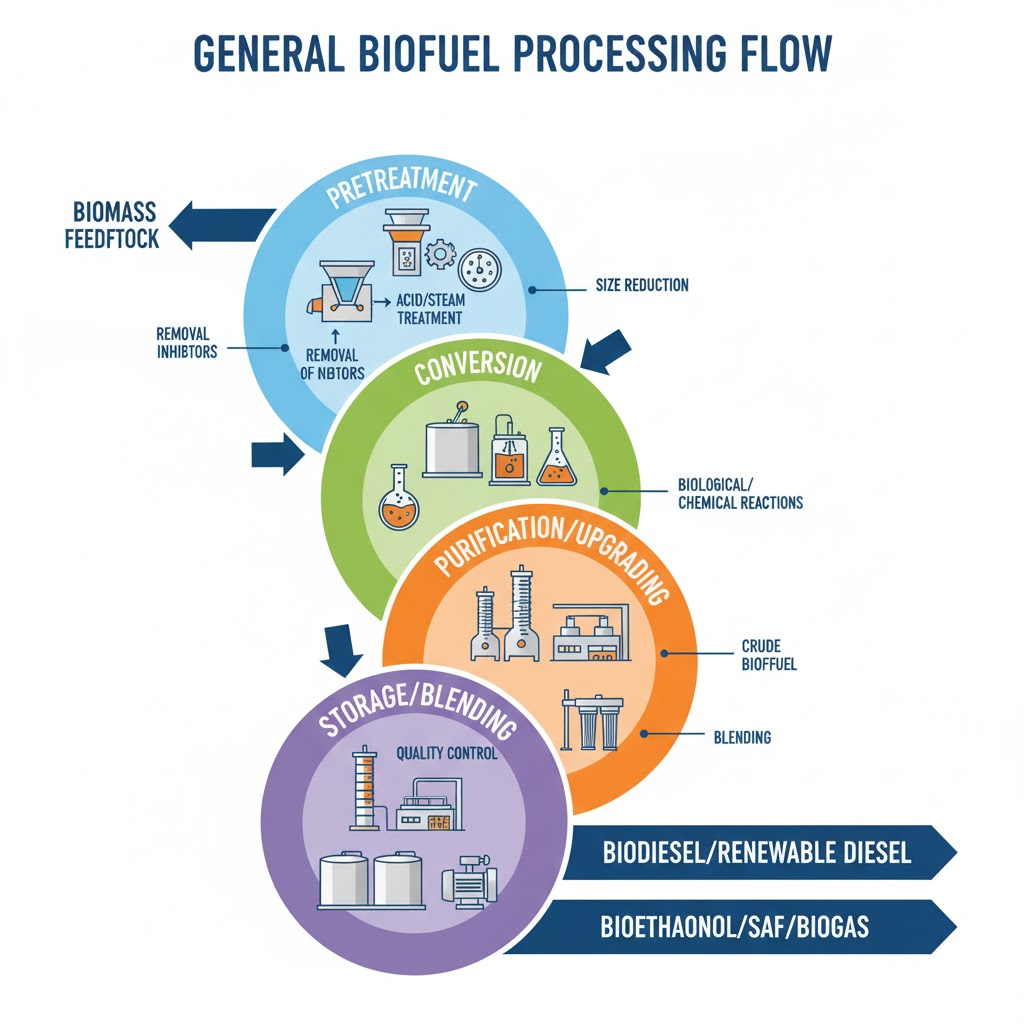

From Feedstock to Fuel — The Generalized Biofuel Processing Flow

At-a-glance steps :

- Pretreatment → Clean/condition feed and remove inhibitors.

- Conversion → Reactions or fermentation produce intermediate fuel streams.

- Upgrading/Purification → Separation, drying, hydrotreating, polishing to meet specs.

- Storage/Blending → Put fuels on spec (B5–B20, E10/E85, SAF blends) and move to market.

Most pathways follow four arcs: (1) Feedstock collection & pretreatment, (2) Conversion, (3) Upgrading/purification, and (4) Storage/blending/distribution. Biological routes (fermentation, anaerobic digestion) focus on clean feed streams and microbe health; thermochemical routes (gasification, pyrolysis, HTL) focus on syngas/bio-oil quality and hydrotreating. Each arc is visible on a thorough PFD.

Feedstock Collection & Pre-Treatment

Oilseeds are cleaned/degummed; WCO/WFO is filtered and neutralized. Starches are milled/gelatinized; lignocellulosics are deconstructed (pretreatment + hydrolysis). Wet wastes are macerated and screened for AD. These steps stabilize variability, remove poisons (e.g., soaps, inhibitors), and set the conversion up for high yield.

Conversion/Reactions

Examples: transesterification (biodiesel), fermentation (ethanol), hydroprocessing/isomerization (HEFA renewable diesel/SAF), anaerobic digestion (biogas), gasification + Fischer–Tropsch (FT liquids), and alcohol-to-jet (ATJ). The reactor section of the PFD will highlight temperatures, residence times, and recycle ratios that govern throughput and selectivity.

Upgrading, Purification & Finishing

Think phase separation, stripping/distillation, drying, hydrotreating, isomerization, and polishing (e.g., final filtration). This is where specs are met—ASTM/EN limits for water, sulfur, oxygenates, glycerin, and stability.

Storage, Blending & Distribution

Finally, finished or blendstock fuels enter tankage and are blended to on-spec products: B5–B20 for diesel users, E10/E15/E85 for gasoline, SAF blends for aviation (with strict rules). Distribution uses rail/road/barges; ethanol rarely uses multi-product pipelines due to water affinity.

Visual to add: biofuel-processing-flowchart-overview.svg

Alt: “Diagram of biofuels being processed: pretreatment, conversion, upgrading, blending across biodiesel, ethanol, biogas, renewable diesel, and SAF.”

Feedstocks Mapped to Conversion Pathways

Oilseeds & Waste Cooking Oil → Biodiesel/Renewable Diesel

Triglyceride/lipid streams route either to biodiesel (FAME) via (acid) esterification + transesterification, or to renewable diesel/SAF (HEFA/HVO) via hydrotreating/isomerization. WCO/WFO adds pretreatment for FFAs and impurities.

When to prefer (added):

- Biodiesel (FAME): Low-capex, quick to deploy; watch cold flow and oxidation stability.

- HEFA/HVO: Drop-in properties for diesel/jet; needs hydrogen and hydrotreaters.

Starch & Sugar Crops → Ethanol/ATJ

Sugars/starches ferment to ethanol, which is later dehydrated/oligomerized/hydrogenated to ATJ-SPK for jet fuel blending (up to 50%).

When to prefer (added):

- Abundant starch/sugar region, existing ferm/distillation expertise, or jet-fuel decarb goals via ATJ.

Lignocellulosic Biomass → Cellulosic Ethanol/FT

Woody residues and ag waste proceed via pretreatment + enzymatic hydrolysis → fermentation (cellulosic ethanol) or gasification → syngas cleanup → FT synthesis for drop-in fuels.

When to prefer (added):

- Forestry/ag residues nearby; desire for drop-in hydrocarbons (FT) or RIN/D3 credit value (cellulosic ethanol).

Organic Wastes & Manure → Biogas/Biomethane

Wet organics enter anaerobic digesters to make biogas (CH₄/CO₂) which is upgraded (H₂S, H₂O, CO₂ removal) to pipeline-quality RNG or used on-site.

When to prefer (added):

- Waste management + energy recovery on farms, WWTPs, and food processors.

Algae & Novel Feedstocks → HEFA/HTL Routes

Lipid-rich algae feed HEFA; whole-slurry microalgae can go via hydrothermal liquefaction (HTL) to bio-crude, then hydrotreating.

When to prefer (added):

- Access to non-arable sites/wastewater; long-term SAF ambitions with wet biomass streams.

Detailed Flow Diagrams by Fuel Type

Biodiesel (Transesterification/Esterification) Process Flow

Degumming & FFA Reduction (Waste Frying Oil/WCO)

WCO/WFO is filtered, degummed, and FFAs are reduced (acid esterification) to avoid soap formation with base catalysts. The PFD often shows a small acid reactor ahead of the main transesterification train.

Catalyst Reaction & Oil–Alcohol Conversion

Neutralized oil reacts with methanol/ethanol (base or solid catalysts) to form FAME + glycerol. Continuous or batch reactors appear with methanol recycle and alcohol recovery columns.

Phase Separation, Washing, Drying & Polishing

After settling/centrifugation, crude FAME is washed to remove residual soaps/glycerol/alcohol, then dried and filtered. Innovations like membrane polishing reduce wash-water use.

Glycerol/Soap Recovery and Purification

Crude glycerol (≈10% of biodiesel mass) is neutralized, stripped of methanol, and upgraded for chemicals, fuels, or anaerobic fermentation—turning a liability into value.

Practical benefits (added):

- Fast to market with modest equipment; watch-outs: soap formation at high FFA, cold-flow limits.

Visual to add: biodiesel-pfd-wco-transesterification.svg

Alt: “Biodiesel PFD for waste cooking oil showing degumming, esterification, transesterification, separation, washing, drying, and glycerol recovery.”

Fuel Ethanol (Fermentation) Process Flow

Milling, Liquefaction & Saccharification

Grains are milled, starch is liquefied with α-amylase, then saccharified to sugars for fermentation. Lignocellulosics add pretreatment + cellulase hydrolysis.

Fermentation, Distillation, Dehydration & Denaturing

Yeast ferments sugars to ~10–15% beer; ethanol is distilled, molecular-sieve dehydrated to anhydrous, then denatured as required by ASTM D4806 before blending.

Co-Products Handling: CO₂ Recovery and DDGS

Whole stillage is decanted/centrifuged into wet cake + thin stillage; evaporated solubles (syrup) blend back to dry DDGS. Fermentation CO₂ can be captured for food/industrial use.

Practical benefits (added):

- Mature technology with strong coproduct value (DDGS); watch-outs: energy intensity of distillation/dehydration.

Biogas/Biomethane (Anaerobic Digestion) Process Flow

Feed Preparation & Digestion

Slurries are screened and homogenized, then fed to mesophilic/thermophilic digesters producing CH₄-rich gas and digestate.

Gas Cleaning (H₂S, Moisture) & Upgrading (CO₂ Removal)

Biogas is desulfurized/dewatered and upgraded (membranes, PSA, amines) to meet pipeline RNG specs (tight H₂S/H₂O/O₂/CO₂ limits vary by utility).

Compression/Liquefaction & Digestate Management

Upgraded gas is compressed (CNG) or liquefied (LNG) for transport; nutrient-rich digestate is managed/valorized to avoid nutrient pollution.

Practical benefits (added):

- Strong waste-to-energy story; watch-outs: digestate handling and meeting gas-grid specs.

Renewable Diesel & SAF via HEFA/HVO Process Flow

Hydrotreating, Isomerization & Fractionation

Lipids are hydrodeoxygenated to paraffins, isomerized for cold flow, then fractionated into diesel/jet/naphtha cuts. HEFA-SPK is an ASTM D7566 annexed synthetic blending component requiring blending with Jet-A.

Co-Product Management (Naphtha/Propane/Water)

HEFA yields light naphtha, propane, and water—each handled on the PFD with recovery and flare/sour-water routing as appropriate.

Practical benefits (added):

- Drop-in quality for diesel/jet; watch-outs: hydrogen supply, catalyst life, and sour-water handling.

Gasification → Fischer–Tropsch (FT) Synthetic Fuels Flow

Syngas Production, Cleanup, FT Synthesis & Upgrading

Solid biomass/MSW is gasified; syngas is cleaned (tars/H₂S removal, H₂/CO trim), then converted over FT catalysts to wax/liquids. Hydrocracking/isomerization tailors jet/diesel fractions. FT-SPK is approved as a blendstock (≤50%) in ASTM D7566.

Practical benefits (added):

- True drop-in hydrocarbons from solid wastes; watch-outs: tar management and syngas conditioning complexity.

Alcohol-to-Jet (ATJ) & Direct Sugars to Hydrocarbons (SIP) Flow

Dehydration, Oligomerization & Finishing

ATJ dehydrates ethanol/isobutanol to olefins, oligomerizes, then hydrogenates to jet-range paraffins (approved ≤50% blend). SIP (farnesane route) adds aromatics via different chemistry and has its own annex.

Practical benefits (added):

- Leverages ethanol supply chains; watch-outs: cost of alcohols and oligomerization selectivity.

Pyrolysis/HTL to Bio-Oil → Upgrading Flow

Stabilization, Hydrotreating & Distillation

Fast pyrolysis creates oxygenated bio-oil needing stabilization + hydrotreating before distillation to fuels. HTL converts wet biomass to bio-crude at high T/P; upgrading resembles petroleum hydroprocessing.

Practical benefits (added):

- HTL handles wet feedstocks; watch-outs: severe hydrotreating and catalyst protection.

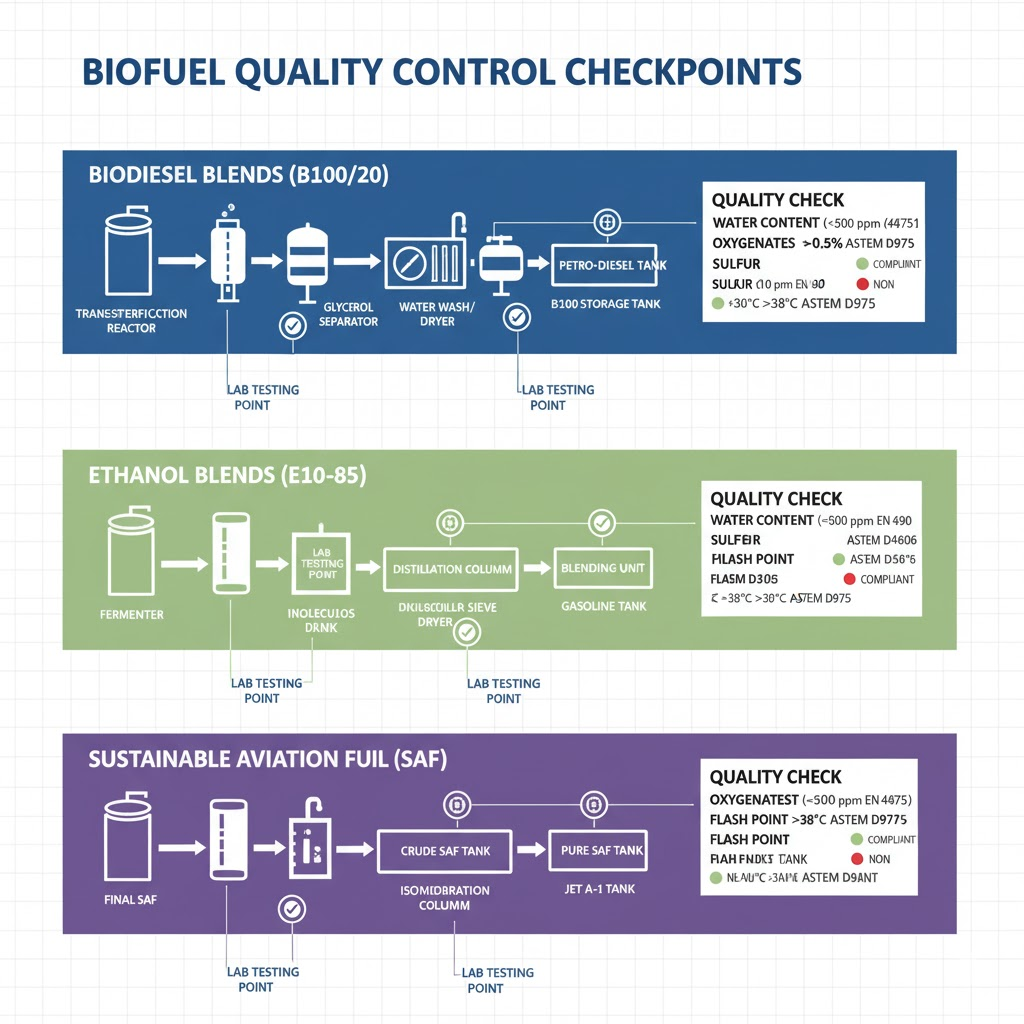

Purification & Quality Control Across Pathways

Quality gates anchor the right side of any PFD. B100 biodiesel must meet ASTM D6751/EN 14214; finished diesel blends follow ASTM D7467/D975. Fuel ethanol must meet ASTM D4806 (ethanol, denaturant, water, acidity, inorganics). SAF blend components meet ASTM D7566 before blending and are re-identified as D1655 Jet-A after blending. These specs keep engines reliable and emissions systems compliant.

Fuel Specifications (ASTM/EN) and Final Product Testing

Labs verify cetane/octane, distillation curves, oxidation stability, and trace contaminants (e.g., metals, chloride). For SAF, the D4054 fit-for-purpose process underpins annex approvals, while D7566/D1655 ensure interchangeability.

Water, Sulfur, and Oxygenate Limits in Finished Fuels

ULSD caps sulfur at 15 ppm; diesel/gasoline also control water/sediment. Gasoline oxygen content (from ethanol) is regulated via E10/E15 waivers and local oxygen requirements; jet fuel allows no free water and tight sulfur limits via D1655. These limits drive many polishing steps on the PFD.

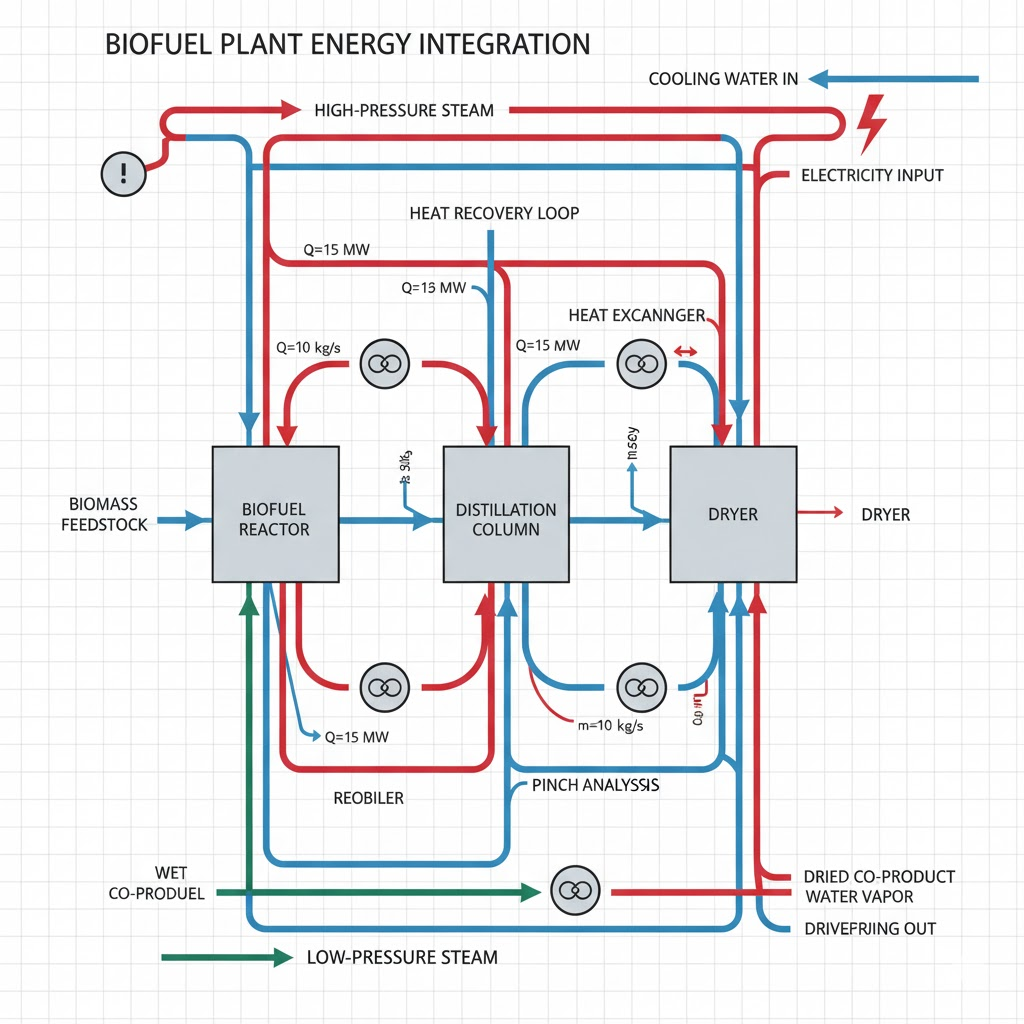

Utilities, Heat Integration & Mass/Energy Balances on the PFD

Great PFDs show steam levels, cooling circuits, and electrical loads next to major equipment. Heat exchangers create networks that pinch-analyze hot and cold streams to cut fuel bills and emissions—often the difference between marginal and profitable plants. Stream tables summarize mass/energy balances for design and scale-up.

Steam, Power, Cooling & Water Networks

Boilers and cogeneration supply steam and power; cooling water/air coolers reject heat; demin/sour-water systems ensure reliability. Utilities are drawn just like process equipment and often have their own PFDs.

Pinch Points and Heat Recovery Opportunities

Pinch analysis maps composite curves to identify minimum utility targets and optimal exchanger matches—essential in energy-intensive steps like distillation, HTL upgrading, and evaporation of stillage.

Environmental Controls & Wastewater/Effluent Handling

Fermentation CO₂ recovery, biodiesel wash-water minimization/reuse, and AD digestate management are as central as the reactors. Biodiesel wash water carries methanol/soaps and needs treatment or advanced membranes; ethanol plants manage stillage via decanter/evaporation to DDGS; AD sites must control nutrients to avoid eutrophication. A credible PFD includes these end-of-pipe systems.

Emissions Abatement (Off-Gas, Odor, VOCs)

Thermal oxidizers, carbon beds, and scrubbers appear where VOCs or odors arise; flare systems handle off-spec gases and hydrotreating off-gas. (Local permits will dictate device choices.)

Effluent Treatment & Solid Residues

Expect DGF/DAF, biological treatment, filtration, and solids dewatering. Glycerol side streams can be upgraded rather than disposed; digestate can be refined to fertilizers/soil products with proper controls.

Safety & Controls in Biofuel Process Diagrams

P&IDs and cause-and-effect charts capture HAZOP outcomes: high-pressure trips, low-level cut-outs on pumps, SIS interlocks per IEC 61511, and relief/flare networks. Tagging follows ISA-5.1, enabling clear loop design and alarm philosophy—your safety net when things get noisy and human.

Critical Control Points, Interlocks & HAZOP Nodes

Nodes often sit at reactors, distillation reboilers/condensers, hydrotreaters, and digesters. Deviations (high T/P, no flow, wrong composition) map to causes, consequences, safeguards, and actions.

Instrumentation Highlights (Flows, Temps, Pressures)

Core loops: FT/FC for feed and recycle, TC/PC for reactors and columns, analyzers for O₂/H₂S/CO₂ in gas cleanup and water content in ethanol/biodiesel. Symbols and tag rules keep everyone aligned.

Storage, Blending & Distribution Schematics

Tankage, Additives & Blend Ratios (e.g., B20, E10/E85, SAF Blends)

Biodiesel typically ships as B100 to blend down to B5–B20 (ASTM D7467). Gasoline blends follow E10/E15/E85 rules. SAF is blended per D7566 annex limits (often 10–50%), then re-identified as Jet-A (D1655). Additives (antioxidants, cold-flow improvers, metal deactivators) are dosed in tankage or on the rack.

Logistics to Pipeline/Rail/Truck/Airport Supply

Ethanol mostly moves by rail/truck/barge—its water affinity makes shared pipelines tricky without dedicated lines. Biodiesel and renewable diesel commonly move through conventional terminals with handling guidelines to manage stability/cold-flow. SAF logistics mirror Jet-A once blended.

Digital Modeling & Simulation of Biofuel PFDs

Simulation platforms like Aspen Plus/HYSYS anchor assumptions (property methods, reaction kinetics, phase equilibria), generate stream tables, and de-risk scale-up. Biodiesel models pick liquid-phase activity methods (e.g., NRTL) for alcohol/oil systems; gasification/FT and hydrotreaters often use Peng–Robinson. Validating against pilot data (yields, energy use, pressure drops) keeps models honest.

Aspen HYSYS/Plus: Assumptions, Property Methods & Validation

Good models state thermo packages, reaction sets, and convergence strategy clearly on the PFD legend or data sheet—and they update as pilots teach new truths. (That discipline saves real money later.)

Using PFDs for Scale-Up (Lab → Pilot → Commercial)

The same PFD evolves: lab (data-rich, simplified equipment) → pilot (closed heat/material balances) → commercial (utilities integration, control/safety layers). Each pass trims risk and CAPEX surprises.

Troubleshooting PFDs & Models

- Mass not balancing? Check hidden vents/drains, unexpected phase splits, and unit losses before tuning efficiencies.

- Recycle won’t converge? Relax specs, add tear streams at logical points, and simplify reaction sets; then tighten.

- Off-spec water/sulfur in product? Revisit polishing steps (dryers, guard beds) and verify analyzer calibration.

- Property method doubt? For alcohol/oil liquid systems use NRTL/UNIQUAC; for hydroprocessing/gasification prefer PR with suitable binary pairs.

Tooling Comparison: Process Simulators

| Simulator | Where it shines | Considerations |

| Aspen HYSYS/Plus | Hydroprocessing, gas processing, solids + detailed thermodynamics | License cost; learning curve |

| ChemCAD | Distillation-heavy flows, education/training | Smaller community for bio-routes |

| PRO/II | Refinery-style hydrocarbon systems | Less common in academic biofuel work |

Advanced Notes (For Process Engineers)

- Use electrolyte NRTL if soaps/ionics affect phase behavior in biodiesel washes.

- For start-up models, ramp utilities and feeds; avoid “instant steady state” illusions.

- Run sensitivity on H₂/HC ratio, isomerization severity, and membrane cut in biogas upgrading to bound economics.

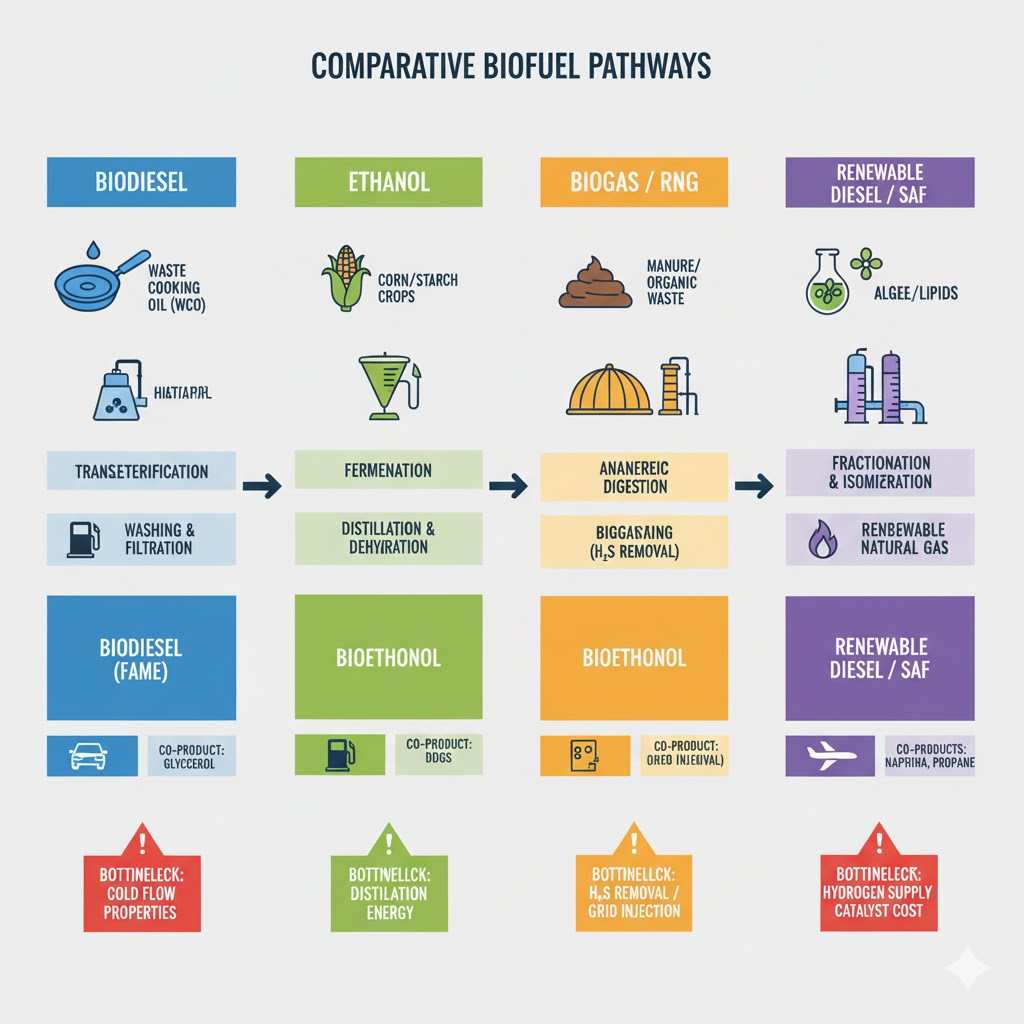

Comparative Flowchart: Biodiesel vs. Ethanol vs. Biogas vs. SAF

Core equipment: Biodiesel (mixing/separation), Ethanol (ferm + distillation + sieves), Biogas (digesters + upgrading), SAF (hydrotreaters/isomerization or FT trains).

Co-products: Glycerol (biodiesel), DDGS & CO₂ (ethanol), Digestate (AD), Naphtha/propane (HEFA).

Bottlenecks: Cold-flow/stability & wash water (biodiesel), energy for distillation (ethanol), contaminant removal & digestate use (AD), hydrogen and catalyst management (SAF/FT).

Quick comparison table (added for clarity & SEO):

| Pathway | Typical Feedstock | Core Steps | Main Fuel Output | Key Co-Products | Frequent Bottleneck |

| Biodiesel (FAME) | WCO/WFO, oilseeds | Degum → (Acid) Esterify → Transesterify → Wash/Dry | B100 / blends | Glycerol | Soap formation, cold flow |

| Ethanol (Starch/Sugar) | Corn, sugarcane | Mill → Liquefy/Saccharify → Ferment → Distill/Dehydrate | Fuel ethanol (E10–E85) | DDGS, CO₂ | Energy for distillation |

| Biogas/RNG | Manure, food waste | Pre-treat → AD → Clean/Upgrade | Biogas / RNG | Digestate | H₂S/CO₂ removal, digestate mgmt |

| HEFA/HVO (RD/SAF) | Oils, fats, algae lipids | Hydrotreat → Isomerize → Fractionate | Renewable diesel / SAF | Naphtha, propane, water | Hydrogen supply/catalyst life |

| FT Liquids | Ligno biomass, MSW | Gasify → Clean → FT → Hydrocrack | Jet/diesel blend components | Wax, naphtha | Tar cleanup, syngas conditioning |

| ATJ/SIP | Ethanol, isobutanol, sugars | Dehydrate → Oligomerize → Finish | Jet blend components | — | Selectivity, cost of alcohols |

—one small action at a time.

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.