Stainless Steel Recycling

Written by Admin | Nov 20, 2025

What Is Stainless Steel? (Families, Grades & Alloying Elements)

Stainless steel is an iron-based alloy that resists rust because it contains at least 10.5% chromium. Other elements—nickel, molybdenum, manganese, nitrogen, and carbon—are blended to tune properties like strength, corrosion resistance, and formability. Stainless families include austenitic (200/300 series), ferritic and martensitic (400 series), duplex (mixed austenite/ferrite), and specialty grades; each family behaves differently in fabrication and in service.

Is Stainless Steel Recyclable?

Quick answer: Yes—stainless steel is 100% recyclable and typically retains its performance after remelting, which is why recovery rates at end-of-life are very high and recycled content in new stainless is substantial.

Yes—stainless steel is 100% recyclable without downgrading its performance, which is why it’s a cornerstone of circular manufacturing. Global studies show high recycled content in new stainless (~60% on average) and very high end-of-life (EoL) collection/recycling rates. An influential Yale/industry study quantified worldwide stainless flows and found an EoL recycling rate around 85% (2015 basis); more recent industry summaries report that ~90–95% of stainless reaching end-of-life is captured and returned to production. The headline: it keeps its value, so people don’t throw it away.

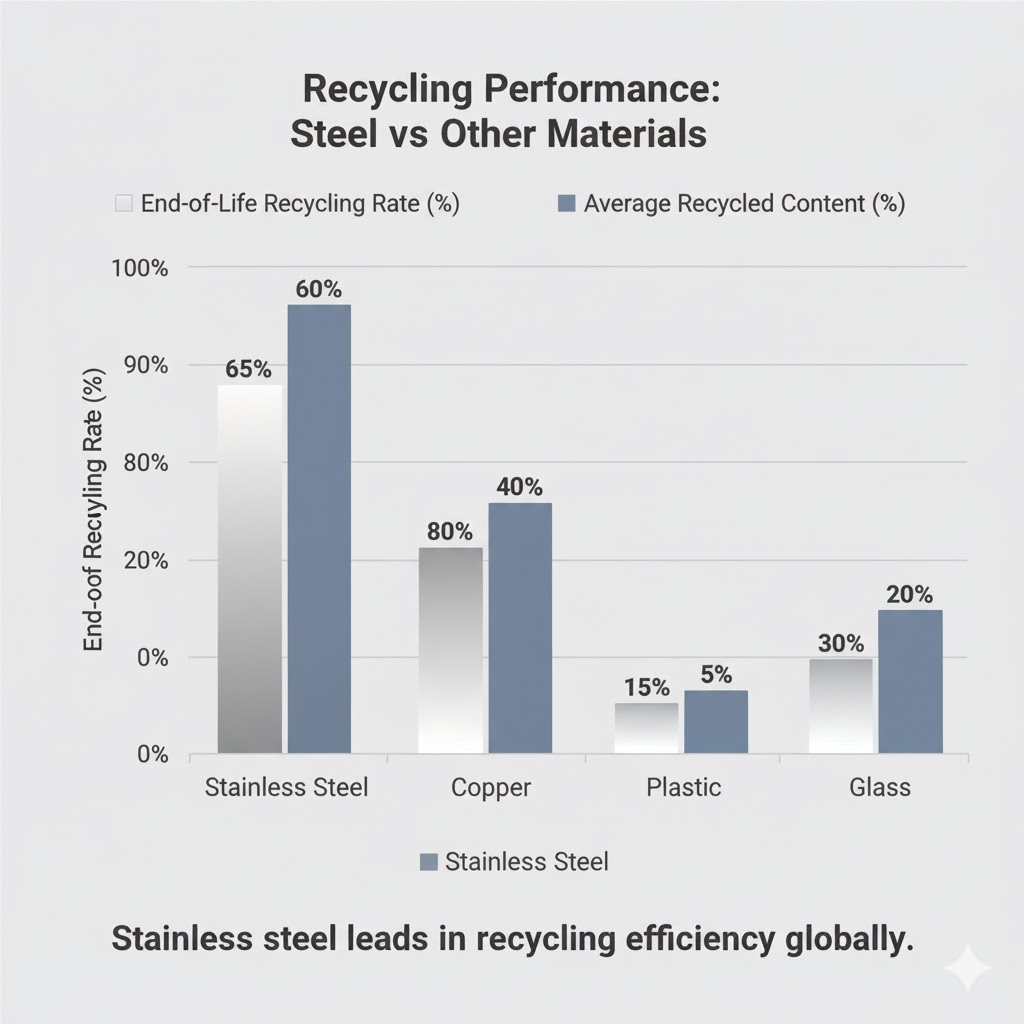

Global End-of-Life Recycling Rates & Recycled Content

Across products and regions, stainless steel’s average recycled content sits near 60% and EoL recycling rates commonly exceed 80%, thanks to strong scrap markets and established recovery networks. High nickel and chromium values help ensure scrap is collected rather than landfilled.

Closed-Loop Recycling vs. Downcycling

Most stainless scrap re-enters stainless production (closed loop). A smaller share can flow to carbon-steel melts when scrap chemistry or logistics fit better (downcycling). Designing take-back and better sorting reduces those losses and keeps alloying elements like nickel and molybdenum in the stainless loop.

How Stainless Steel Is Recycled (Step-by-Step)

Quick steps (snippet-ready):

- Collect reclaimed (“old”) and industrial (“new”) scrap.

- Sort by grade; confirm with PMI tools (magnet test has limits).

- Shear/shred bulky items; bale for efficient charging.

- Melt in an Electric Arc Furnace (EAF) with alloy additions as needed.

- Refine chemistry in AOD/VOD to hit carbon/impurity targets while preserving chromium.

- Cast, then hot/cold roll to final forms.

- Ship with test certificates to ensure traceability.

Collection & End-of-Life Scrap Streams

Scrap comes from two main streams: reclaimed (old) scrap from worn equipment, buildings, appliances, etc., and industrial (new) scrap from manufacturing offcuts and turnings. Both streams feed mills and foundries as high-value raw material.

Sorting & Identification (Magnet Test Limits, XRF/LIBS/OES)

First-pass sorting separates stainless from other metals. Magnet checks help—but beware: austenitic grades (e.g., 304/316) can become slightly magnetic after cold work, so magnet response alone is not a reliable ID method. Recyclers rely on positive material identification (PMI) tools: handheld XRF for non-destructive chemistry, LIBS for carbon/low-alloy separation (e.g., 316 vs. 316L), and OES when precise light-element measurements (like carbon) are required.

Plain-English tooltips:

- PMI: a quick scan that reads the alloy’s “ingredient list.”

- XRF: great for most alloying elements, fast and non-destructive.

- LIBS: helpful when you need more detail on light elements.

- OES: high-precision analysis when exact chemistry matters.

Size Reduction & Baling

Bulky items are shredded or sheared to consistent sizes; clean, dense bales lower transport cost and improve furnace charging efficiency. Facilities use hammermills, alligator shears, and balers to compact scrap while maintaining grade separation.

Melting in Electric Arc Furnaces (EAF)

Prepared stainless scrap, plus necessary alloy additions (e.g., ferrochrome, ferronickel), is melted in an EAF—a flexible, electricity-driven steelmaking route optimized for high-scrap charges.

Plain-English note: Think of the EAF as a giant electric oven that melts sorted scrap quickly and efficiently.

AOD/VOD Refining & Alloy Adjustment

Molten steel is transferred to AOD (argon-oxygen decarburization) or VOD/VD vessels to remove carbon while minimizing chromium loss and to fine-tune sulfur, nitrogen, and other elements. This stage delivers the exact chemistry needed for each grade.

Plain-English note: AOD/VOD is where the “recipe” is perfected so the final steel meets spec.

Casting, Hot/Cold Rolling & Finishing

After refining, the steel is cast into slabs, blooms, or billets, then hot-rolled and (if needed) cold-rolled and annealed to achieve final thickness, strength, and surface finish for sheet, plate, bar, wire, or tube.

Quality Assurance & Traceability

Every heat is linked to mill test certificates (EN 10204 3.1/3.2) and heat numbers that document chemistry and mechanical properties. This traceability underpins compliance (often tied to ISO 9001) and lets buyers verify grade and origin long after production.

Stainless Steel Scrap Types & Grades

Quick-reference table (adds user value without repeating later content):

| Family / Grade | Typical Magnetism | Notable Alloying | Common Uses | Scrap Value Trend* |

| 300 series (304, 316) | Non-magnetic (can become slightly magnetic after cold work) | Ni; 316 adds Mo | Kitchens, marine/chem (316) | Higher (Ni/Mo content) |

| 400 series (409/410/430) | Magnetic | Low/No Ni; Cr-rich | Appliances, auto trim | Lower vs 300 |

| 200 series | Mostly non-magnetic | Mn/N substitutes for some Ni | Appliances, cookware | Lower vs 300 |

| Duplex & specialty | Mixed | Higher Cr/Mo/Ni as specified | Oil & gas, chemical | Premium grades |

300 Series (304, 316) — Austenitic, Nickel-Bearing

Non-magnetic in the annealed state; excellent corrosion resistance. 316 contains molybdenum for chloride environments. Highly sought scrap due to nickel/moly content.

400 Series (409, 410, 430) — Ferritic/Martensitic, Magnetic

Chromium-rich with little or no nickel; generally magnetic and lower scrap value per pound than 300 series but widely recycled.

200 Series — Manganese-Bearing Alternatives

Lower-nickel austenitics that substitute manganese/nitrogen for part of the nickel—still recyclable, but scrap pricing reflects lower Ni content.

Duplex & Specialty Grades (High-Moly, High-Ni)

Mixed austenite/ferrite structure for superior strength and stress-corrosion performance; specialty high-Ni/Mo grades command premium scrap values.

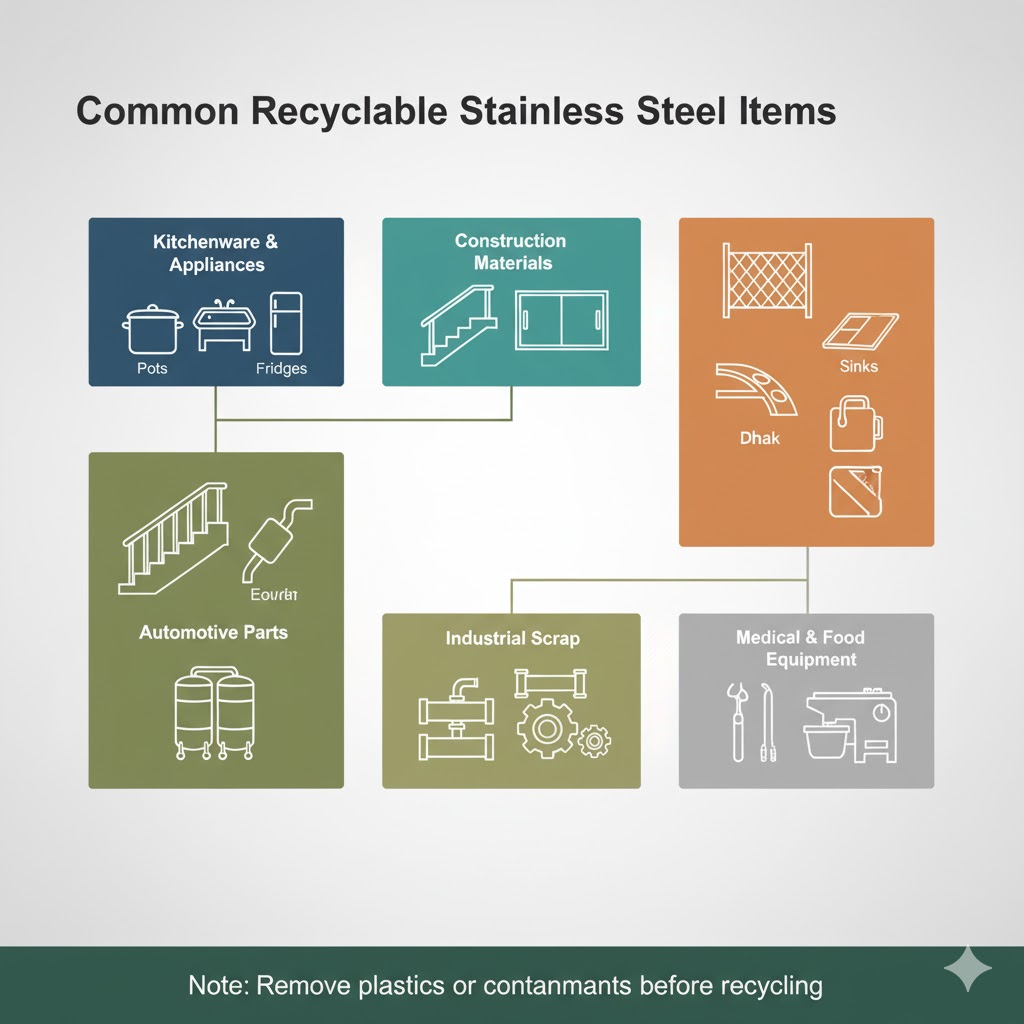

What Stainless Steel Items Can Be Recycled?

Tip: Remove electronics/batteries and obvious contaminants first; ask your recycler about any de-contamination steps for medical/food-grade items.

Kitchenware & Appliances

Pots, pans, sinks, refrigerators, and dishwashers are recyclable metal; local curbside rules vary, but scrap yards and drop-off centers will accept them.

Construction & Architectural Materials

Handrails, cladding, fasteners, mesh, and structural elements from renovations/demolition are standard stainless scrap streams.

Automotive & Transportation Parts

Exhaust components, trim, tankers, and rail/ship hardware often contain recyclable stainless.

Industrial & Manufacturing Scrap

Offcuts, turnings, tanks, pipework, valves, and process equipment provide steady high-grade scrap for mills.

Medical, Food-Grade & Hygiene Equipment

Surgical instruments, sanitary tubing, and food-processing gear are common sources—handled with appropriate de-contamination and documentation.

How to Prepare Stainless Steel Scrap for Maximum Value

(Add this printable checklist at the top of the section; your original subsections remain below.)

Checklist:

- Sort by grade & form (304, 316, 400-series; solids vs turnings).

- Remove attachments/contaminants (plastics, rubber, coatings, oils/coolants).

- Keep “clean” vs “dirty” scrap separate and label bins clearly.

- Bundle/secure loads; include any heat numbers/MTCs to support traceability.

Separate by Grade & Alloy

Keep 304, 316, 400-series, turnings, and mixed “breakage” in distinct bins. Good segregation can earn meaningful price premiums.

Remove Contaminants & Attachments (Plastics, Rubbers, Coatings)

Strip non-metal parts (handles, gaskets, coatings) and fluids. Cleaner scrap reduces deduction and improves your payout.

Keep “Clean” vs. “Dirty” Scrap Separate

“Clean” stainless (no attachments) typically sells higher than “dirty.” Label containers and maintain housekeeping to protect value.

Weighing, Documentation & Safe Handling

Bundle securely, label grades, and include any paperwork (e.g., heat numbers). Follow safety guidance for cutting, shredding, and handling.

Troubleshooting (new)

- Load rejected for “mixed metals”? Re-sort and tag by grade; keep copper/brass away from stainless.

- Coolant-wet turnings? Drain and separate; wet, oily turnings often face deductions.

- “304 turned magnetic”—is it wrong? Cold work can induce slight magnetism; confirm with PMI.

- Cookware still has plastic handles? Remove to avoid “dirty” deductions.

Case study (new):

A small fabrication shop labeled separate bins for 304 solids, 316 solids, and turnings. Within one month, payouts improved versus prior mixed loads—simply by keeping alloys and forms apart.

Stainless Steel Recycling Prices

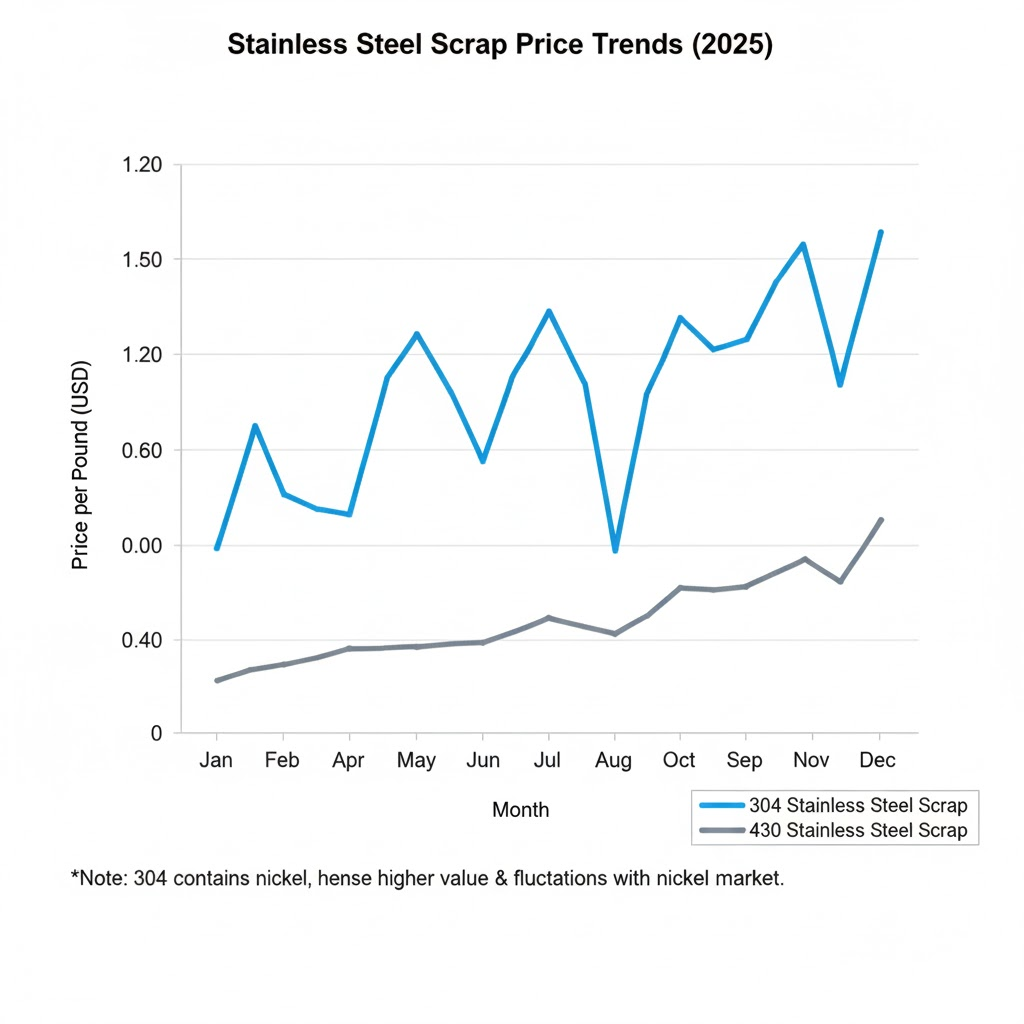

In one line (snippet-ready): Prices mainly track grade/chemistry (nickel, molybdenum content) and regional demand, with volatility closely linked to nickel markets.

What Drives Price (Grade, Nickel Market, Location, Volume, Cleanliness)

Scrap prices move with alloy content (Ni/Mo), regional demand, load size, and cleanliness. Stainless and nickel markets are closely linked; recent years saw nickel oversupply and volatility, which flowed through to stainless scrap pricing.

Where to Check Today’s Prices & Indexes

For current benchmarks and regional assessments, consult Argus Metals (stainless scrap indices) and similar services; for quick yard checks, tools like iScrap App and Metaloop provide crowd-sourced or indexed snapshots.

Tips for Selling to Yards & Brokers

Call ahead for grade specs, minimums, and ID requirements; ask how they treat mixed loads and turnings; and reference reputable indices to time larger sales. Many yards adjust offers daily as LME nickel moves.

Environmental Benefits of Recycling Stainless Steel

Energy & CO₂ Savings vs. Primary Production

Recycling stainless cuts energy use and emissions substantially. A landmark analysis showed that, compared with “all-virgin” production, today’s scrap-fed operations already save ~33% energy globally—and a hypothetical 100%-recycled feed could save roughly half again.

Conserving Chromium, Nickel & Molybdenum

Closed-loop recycling preserves critical alloying elements—reducing mining, conserving resources, and stabilizing supply for future products.

Circular Economy Impacts & Longevity

Because stainless lasts for decades and can be endlessly recycled without losing quality, it’s a model circular material: durable in use, valuable at end-of-life.

Where & How to Recycle Stainless Steel

Find options near you (new helper):

- Check your city’s recycling page for metal rules.

- If curbside won’t take cookware/appliances, use a recycler locator or search “stainless scrap yard near me.”

- For larger loads, ask about pickup, minimums, and deductions.

Household Drop-Offs vs. Commercial Programs

Most curbside programs don’t accept cookware or bulky metal; use municipal drop-off sites or scrap yards instead. Always check local rules—some cities do accept metal cookware in the bin, but it’s the exception.

Selecting a Responsible Recycler (Certifications & Practices)

Look for recyclers with clear environmental and quality systems (e.g., ISO 14001 for environmental management and ISO 9001 for quality/traceability). Industry-specific programs like RIOS signal integrated quality, environment, and safety management.

Curbside vs Drop-Off vs Scrap Yard (new comparison)

| Option | Accepts bulky stainless? | Pays you? | Pros | Considerations |

| Curbside bin | Rarely | No | Convenient | Many programs exclude cookware/appliances |

| City drop-off | Sometimes | No | Wider acceptance | Transport is on you |

| Scrap yard | Yes | Yes | Best payout; grade-specific | May require ID, minimums, clean loads |

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.