Best Flexible Van Solar Panels

Written by Admin | June 22, 2025

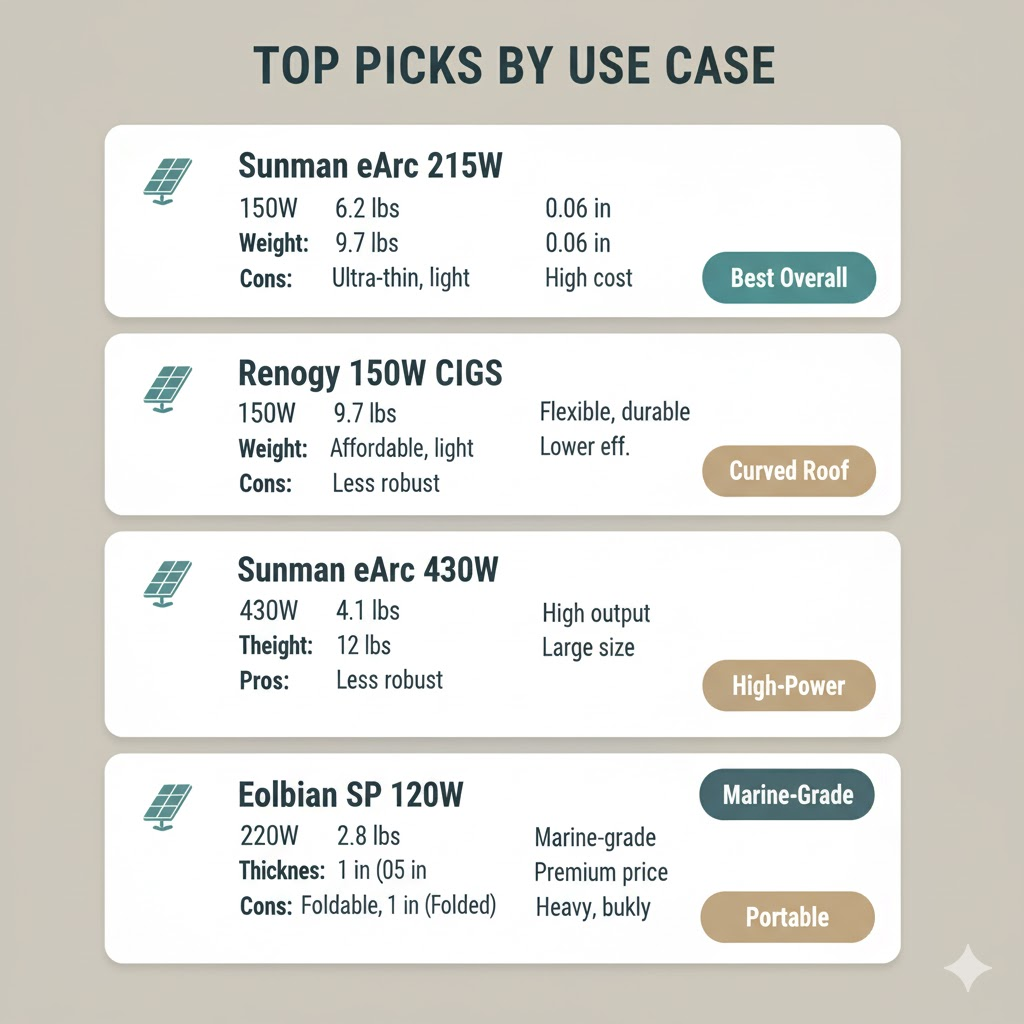

Top Picks at a Glance

Best Overall Flexible Panel for Vans

Sunman eArc 215W “half-cut / shade-resistant” — Glass-free, ultra-light, low-profile, and backed by mainstream certifications; excellent balance of output, weight, and durability for van roofs. (Sunman’s eArc line carries IEC/UL certifications and a product warranty up to 10 years on certain models.)

Specs snapshot (add from datasheet when publishing): ~1615×710×≈2 mm; ~3–4 kg; mono half-cut; laminate.

Pros: thin/stealth; strong watts-per-area; certified line; quieter at speed.

Cons: laminate installs demand good heat management (air gap) and correct adhesive pattern.

Best CIGS Thin-Film Panel for Curved Roofs

Renogy 150W CIGS Flexible — True thin-film module that conforms to tighter curves than typical mono “semi-flex” panels and is more forgiving in partial shade; IP68 build with integrated bypass protection.

Specs snapshot: ~1658×646×~1.5 mm; ~3 kg; CIGS; J-box/connectors commonly IP67/68.

Pros: excellent curvature tolerance; kinder shade behavior; light.

Cons: lower watt density vs high-power mono laminates; higher $/W.

Best Budget Pick

Renogy 100W Flexible (Monocrystalline) — Widely available, light, and inexpensive; a practical starter panel for small vans and weekenders.

Specs snapshot: ~100 W; ~1.9 kg; mono; mono; J-box/MC4 typically IP67–68.

Pros: affordable; easy to source; beginner-friendly size.

Cons: shorter product warranties than rigid panels; mind bend radius.

Best High-Power Semi-Flexible (e.g., eArc-style)

Sunman eArc 430W — Among the highest-wattage flexible modules on the market; ideal when you want maximum roof output without a framed array.

Specs snapshot: ~425–430 W class; laminate; check controller voltage limits.

Pros: huge output in single laminate; certified family; strong performance warranty.

Cons: ensure MPPT and roof layout support size and V/I.

Best Marine-Grade Option for Harsh Weather

Solbian SP Series (e.g., SP118/130W) — Premium Italian-made, ultra-thin marine panels with high-efficiency back-contact cells; purpose-built for vibration, salt, and UV.

Specs snapshot: ultra-thin; marine laminate; SunPower back-contact cells.

Pros: marine-proven; UV/salt tolerant; configurable.

Cons: highest cost per watt.

Best Portable Foldable Alternative

EcoFlow 220W Bifacial Portable Panel — For travelers who prefer not to glue anything to a roof; IP68, fast setup, pairs cleanly with power stations.

Specs snapshot: 220 W bifacial; foldable; carry case/stand.

Pros: no permanent install; park van in shade, panel in sun.

Cons: daily setup/pack-down; storage/theft management.

What to Know Before You Buy

How It Works (plain-English add-on)

Solar cells make DC power that changes with sunlight and temperature. Van roofs are small, so every watt counts. MPPT charge controllers “translate” higher panel voltage into extra charging current—this matters a lot when you have limited roof area. A good MPPT + correct wiring often yields meaningfully more daily Wh than the same array on PWM.

Mini Glossary (drop-in for AEO)

- ETFE vs PET: ETFE is a tougher, more UV-resistant top sheet; PET is cheaper but can yellow sooner.

- Bend radius: the gentlest curve a panel can safely follow; tighter risks micro-cracks.

- Vmp/Voc/Imp/Isc: panel voltage/current at max power, open-circuit, etc.—used to size controllers/wiring.

- IP67/IP68: ingress-protection for dust/water; higher = better moisture resistance.

- Bypass diodes: let current flow around shaded cell groups, reducing hot spots and power loss.

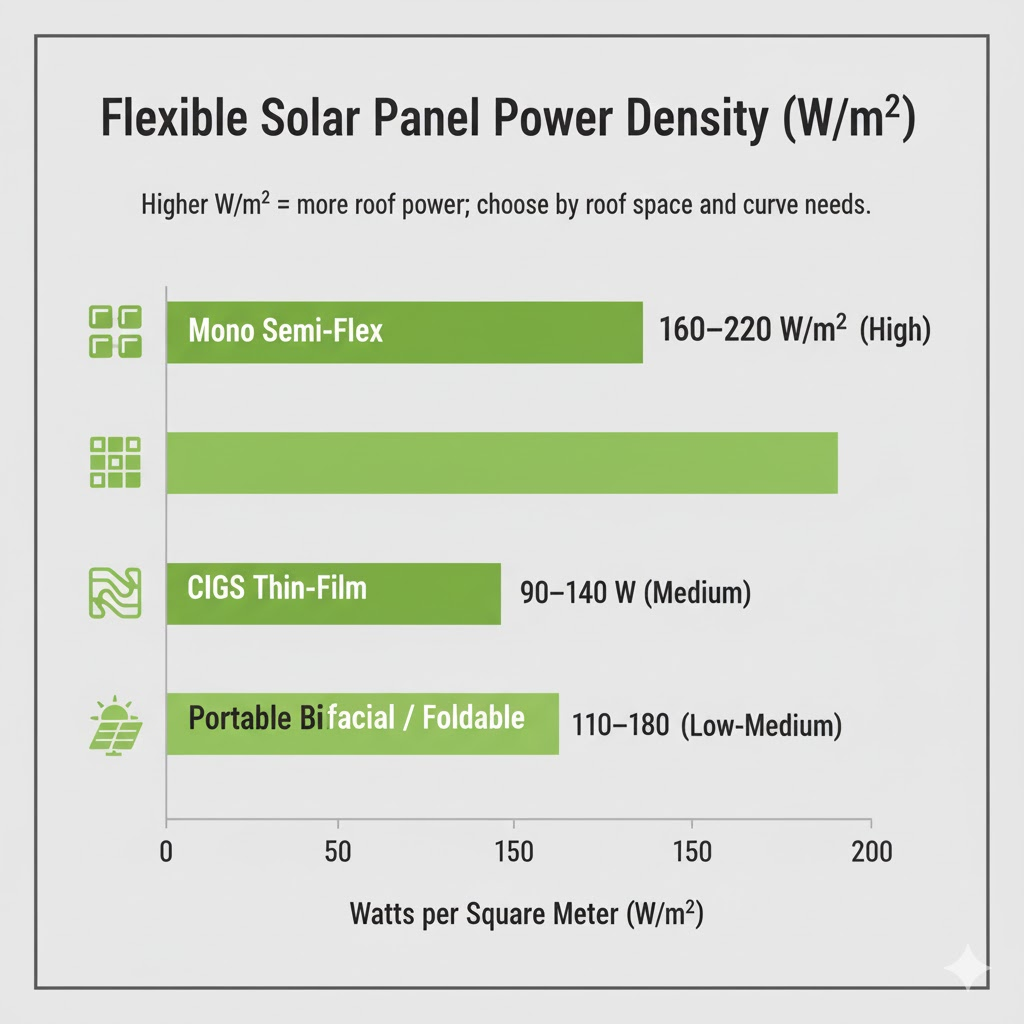

Flexible Panel Technologies (Monocrystalline vs CIGS vs “Semi-Flexible”)

Most “flexible” van panels are actually semi-flexible mono modules: standard silicon cells laminated in polymer instead of glass, making them thin and light but usually less robust than rigid modules. CIGS thin-film panels use a different absorber (copper indium gallium diselenide) that can be deposited on foil; they’re truly flexible, tolerate curvature better, and often behave more kindly in sub-optimal light—though typical watt-per-area is lower and prices can be higher.

Voice-friendly Q: Which tech suits my van—mono semi-flex or CIGS thin-film?

- Choose mono semi-flex for best W/m² and straightforward sourcing.

- Choose CIGS for tighter curves or complex shade patterns.

Wattage & Roof-Space Planning for Vans

Measure usable roof real estate (clear of vents/antennae), then back into watts from your daily Wh needs (see sizing section). High-power semi-flex options like 215–430W eArc modules can reduce panel count on short roofs, while 50–120W class modules suit micro-campers. Check each panel’s dimensions on its datasheet before committing.

Add a visual: simple roof grid showing fan, skylight, rails; mark obstacles and wire paths.

Minimum Bend Radius & Roof Curvature

Every flexible panel has a manufacturer-specified minimum bend radius—exceeding it risks micro-cracks and early failure. Treat “can bend” as “can bend a little,” not like a yoga mat, and only bend during installation. Always follow the panel’s manual for curvature limits.

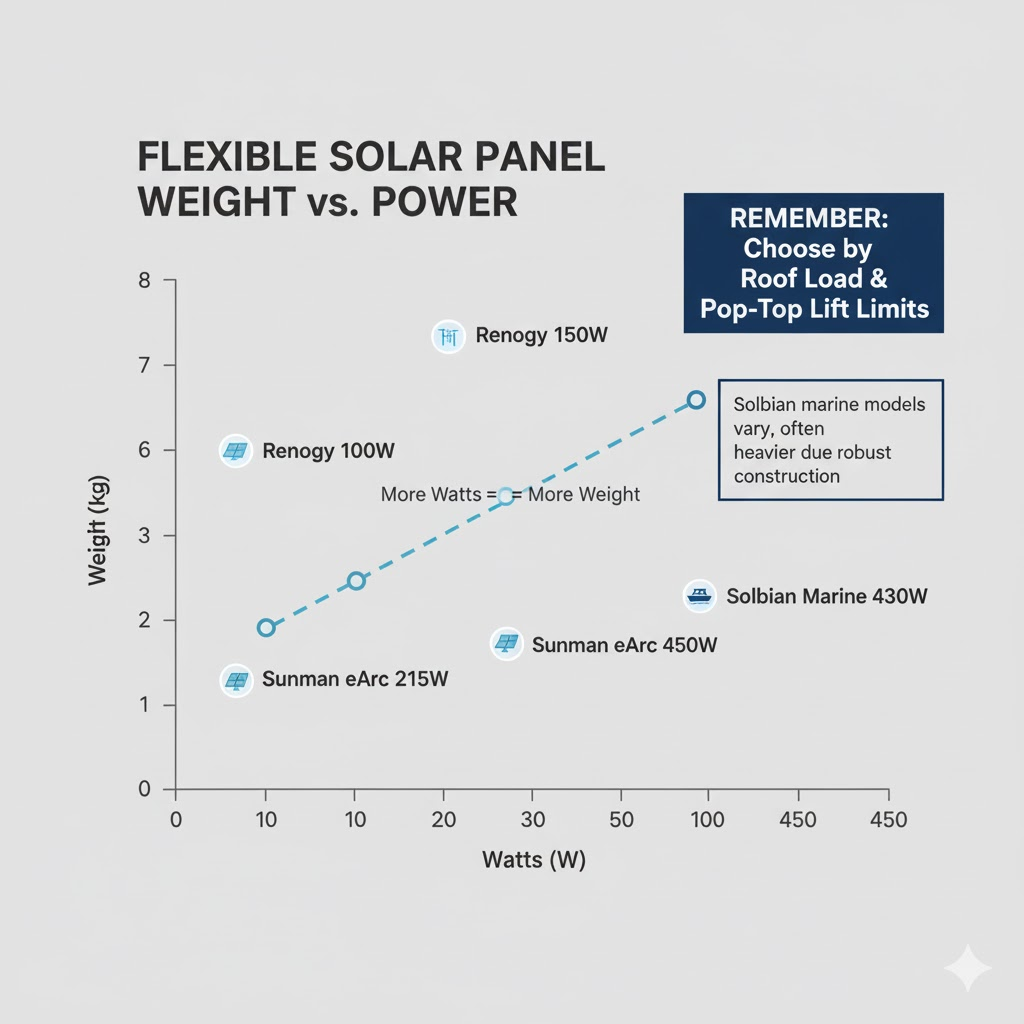

Weight, Thickness & Low-Profile “Stealth” Considerations

Glass-free laminates cut visual profile and wind noise and help stealth builds. eArc-style modules can be just a few millimeters thin yet deliver hundreds of watts; premium marine laminates (e.g., Solbian SP series ~2 mm thick) virtually disappear on the roof.

Durability: ETFE vs PET, UV Resistance & Micro-Crack Risks

ETFE top sheets resist UV and scuffing better than older PET films. Still, flexible modules run hotter than framed glass modules and are more vulnerable to micro-cracks from flexing and foot traffic—choose brands with proven encapsulation and follow mounting guidance to manage heat.

Shade Tolerance, Cell Layout & Bypass Diodes

Partial shade hammers any panel, but thin-film (CIGS) modules can be more forgiving because of their cell structure. Regardless of tech, look for modules with well-implemented bypass diodes to limit hot-spot risk and keep some output when a section is shaded.

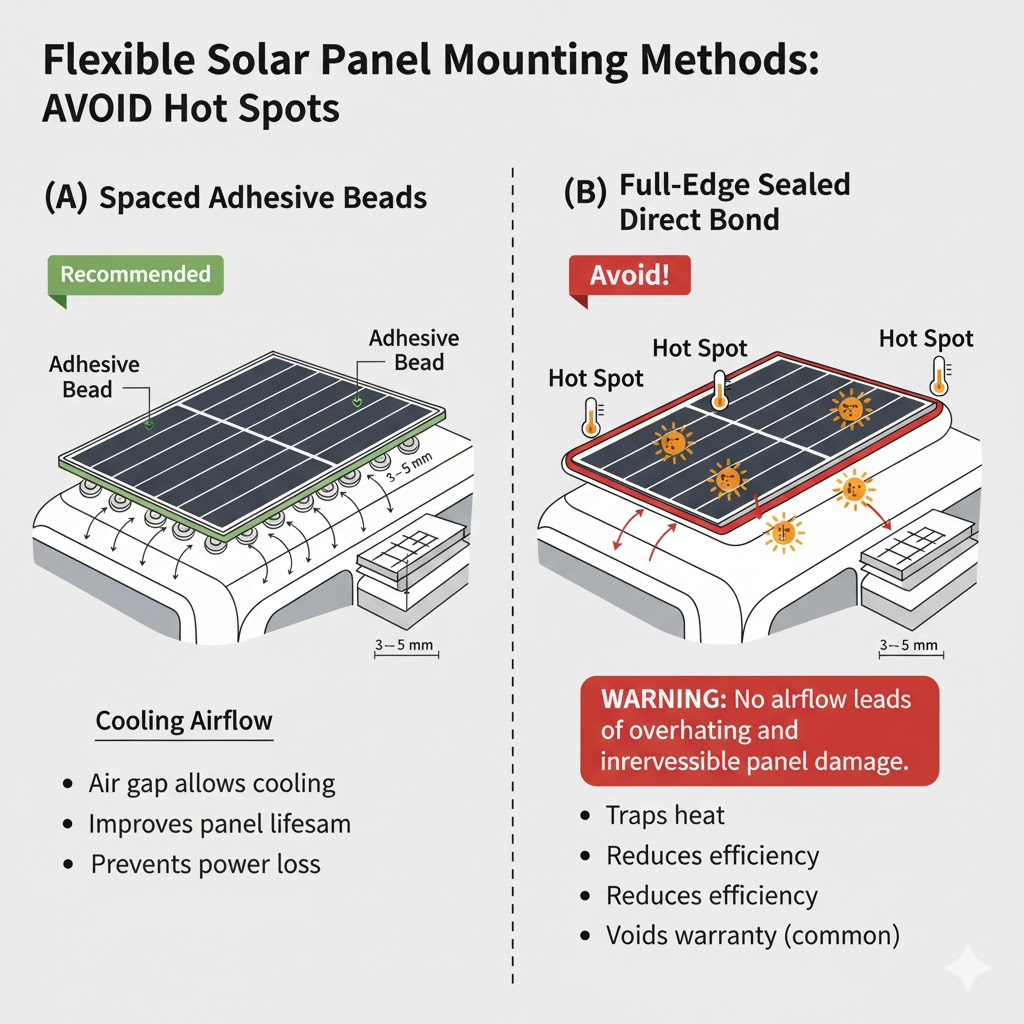

Heat Management: Air Gap vs Direct-Bond Mounting

Avoid sealing edges and avoid completely “smothering” a panel to the roof. Manufacturer guidance commonly recommends adhesive in beads/strips to maintain a small air channel; this helps cooling and longevity and improves drainage. Some warranties exclude fully edge-sealed or zero-gap installs.

Add a visual: “Apply adhesive in spaced beads parallel to airflow; keep ~3–5 mm air gap. Do not edge-seal.”

Certifications, IP Ratings & Warranties

Prioritize modules with standard safety/performance certifications (e.g., IEC 61215/61730, UL). Check IP ratings (IP67/IP68) for junction boxes/connectors and read warranty terms—many flex panels have shorter product warranties (e.g., 2–5 years), but some (e.g., Sunman eArc) offer longer product coverage on select models.

Best Flexible Van Solar Panels — In-Depth Reviews

Pick #1 — Best Overall

Sunman eArc 215W Half-Cut

Why it stands out: Excellent watts-per-footprint, mainstream certifications, and a glass-free build that hugs van roofs for a tidy, wind-quiet look. Half-cut interconnects aid in shade resilience versus older layouts, and the eArc family carries robust certification and product-warranty terms for a flex panel. Best for full-timers wanting “fit-and-forget” simplicity without frames.

Specs snapshot (add from datasheet): size ~1615×710×≈2 mm; ~3–4 kg; half-cut mono; laminate.

Pros: stealth profile; strong W/m²; certified range.

Cons: needs airflow gap; avoid edge sealing.

Real-world use: commonly powers a 12 V fridge, lighting, fans, device charging for solo travelers with ~200 Ah LFP.

Pick #2 — Best CIGS Thin-Film

Renogy 150W CIGS Flexible

Why it stands out: Real thin-film module that conforms to curves most mono panels can’t, with IP68 construction and integrated bypass protection. CIGS architecture is known for kinder behavior in uneven light—useful on cluttered roofs and urban parking. Great match for high-curvature vans and stealth builds.

Specs snapshot: ~1658×646×~1.5 mm; ~3 kg; CIGS; J-box/connectors typically IP68.

Pros: superb curvature; friendlier in patchy shade; light.

Cons: lower watts per area; higher $/W.

Pick #3 — Best Budget

Renogy 100W Flexible (Monocrystalline)

Why it stands out: Accessible price, broad availability, and straightforward mounting. Perfect for starter systems or as a supplement to alternator/DC-DC charging on weekenders. Keep expectations realistic on lifespan and avoid edge-sealing for thermal reasons.

Specs snapshot: ~100 W; ~1.9 kg; mono; flex rating per datasheet.

Pros: inexpensive; easy to source; compact footprint.

Cons: shorter product warranty; mind bend radius.

Pick #4 — Best High-Power Semi-Flexible

Sunman eArc 430W

Why it stands out: Massive output in a single glass-free laminate—ideal when space is limited but power needs aren’t. Excellent for electrified kitchens, large fridges, or digital nomads running heavy loads. Ensure your MPPT and roof layout can handle its voltage/current.

Specs snapshot: ~425–430 W class; laminate; check Vmp/Voc against MPPT limit.

Pros: huge watts per panel; strong performance warranty.

Cons: larger laminate—plan routing/strain relief carefully.

Pick #5 — Best Marine-Grade

Solbian SP Series (e.g., SP118/130W)

Why it stands out: Premium marine panels engineered for vibration, salt, and UV with high-efficiency back-contact cells; favored in sailing where failure isn’t an option. Pricey on a per-watt basis, but the build pedigree is unmatched for harsh environments.

Specs snapshot: ultra-thin marine laminate; SunPower back-contact; custom junction options.

Pros: premium durability; high efficiency; marine heritage.

Cons: cost per watt.

Pick #6 — Best Ultra-Light

Sunman eArc 100W (or similar)

Why it stands out: For micro-campers and pop-tops where every kilogram counts. Ultra-thin eArc-style laminates provide real output with barely-there profile and weight, easing lift mechanisms and reducing roof resonance.

Specs snapshot: ultra-thin; very light; check variant datasheet.

Pros: minimal weight; ideal for pop-tops.

Cons: lower absolute watts per panel.

System Sizing for Van Life

Estimating Daily Energy Use (Wh)

List your devices (fridge, lights, fans, chargers, pump, laptop), note watts and hours per day, then sum to daily Wh. Add ~20–30% headroom for weather and inverter losses to size your array thoughtfully.

Matching Panel Watts to Battery Bank (AGM vs LiFePO₄)

AGM prefers shallower cycles; LiFePO₄ welcomes daily cycling and faster charge acceptance. As a rough feel, a 200–300Ah LiFePO₄ bank pairs nicely with ~300–450W of flex PV for full-time use; weekenders can thrive on ~100–200W feeding 100–200Ah.

MPPT vs PWM Charge Controllers (What Vans Should Use)

MPPT controllers convert excess panel voltage into additional charging current—crucial with higher-V panels and cool mornings. PWM is simpler/cheaper but leaves harvest on the table. Vans with limited roof area benefit disproportionately from MPPT.

Series vs Parallel Wiring on a Van Roof

Series wiring boosts voltage (thinner cabling, better MPPT efficiency) but one shaded panel drags the string. Parallel keeps voltage low and current high (thicker wire, fusing/combiner needed) but isolates shading to the affected panel. Many van builders choose parallel or split-strings for shade resilience.

Suggested System Sizes (Weekend / Full-Time / Off-Grid Heavy Use)

Weekender: 100–200W flex + 50–150Ah battery + compact MPPT.

Full-time digital nomad: 300–450W flex + 200–300Ah LiFePO₄ + 30–50A DC-DC + 30–50A MPPT.

Off-grid heavy use: 500–600W flex/semi-flex (or combine with a small rigid rack) + 300–400Ah LiFePO₄ + inverter 2–3kW + robust alternator charging.

Advanced Users: Pro sizing & safety notes (add-on)

- Voltage headroom: ensure Voc (cold) of your array < MPPT max input; leave margin.

- Current protection: fuse strings/combiners to ≥1.25× Isc (per string) and obey controller guidance.

- Cable gauge & drop: target ≤2–3% drop at Imp; use calculator and adjust gauge/route.

- Temp coefficient: hot roofs reduce power; airflow matters.

- Stringing: consider 2S2P layouts for resilience vs shade while keeping MPPT within limits.

Installation Overview (Van-Specific)

Adhesive Mounting (VHB/Sikaflex) vs Mechanical Fastening

For stealth and weight savings, most van owners bond panels. Follow manufacturer guidance: use adhesive beads or spaced pads (e.g., VHB + polyurethane) to keep a cooling channel; don’t seal edges—trapped heat and moisture shorten life. Mechanical rails add air flow and serviceability if height allows.

Cable Routing, Glands & Waterproofing

Use purpose-made IP-rated cable glands and UV-stable sealants. Keep drip loops, protect cables from chafe, and land PV cables into the MPPT with proper fusing/breakers per your controller manual.

Maintaining an Air Gap & Reducing Roof Heat Transfer

A few millimeters of consistent standoff dramatically improves thermal behavior. Many install guides now caution against full-sheet bonding specifically to avoid heat buildup and water-pooling under the laminate.

Pop-Top, High-Roof & Curved-Roof Tips

On pop-tops, choose ultra-light modules to preserve lifting effort; verify the roof’s curvature against the minimum bend radius before committing. On high roofs, lay panels to avoid shadows from racks and vents at mid-day angles.

Maintenance, Cleaning & Troubleshooting

Keep surfaces free of grime and pollen; check bond lines and strain relief each season. If output drops unexpectedly, inspect for hot spots/shading, loose MC4s, or a failed bypass diode (MPPT logs help confirm).

Troubleshooting quick table (add-on)

- Output collapses at noon → Likely partial shade/hot spot → Inspect shading, verify bypass diodes, check MC4s.

- MPPT “Over-voltage” alert → Voc (series) exceeds controller limit → Rewire parallel or upgrade controller.

- Panel extremely hot → No airflow/edge-sealed → Re-mount with spaced adhesive beads to create air gap.

- Water ingress at gland → Incorrect sealant/strain relief → Re-seal with UV-stable sealant; add drip loop.

Flexible vs Rigid Panels on Vans

Efficiency & Real-World Performance

Rigid glass-laminated modules typically run cooler and more efficiently for decades. Flexible modules offer lower profile and weight but accept a trade-off in peak output per area and thermal performance. Choose based on your roof height limits and stealth priorities.

Aerodynamics, Noise & Fuel Economy

Low-profile laminates reduce wind loading and potential whistle, especially on tall vans. That said, a tidy rigid rack with rounded edges is also quiet at speed; weigh this alongside serviceability.

Lifespan, Degradation & Repairability

Flexible modules generally carry shorter product warranties and can be harder to remove if the bond fails; rigid panels last longer and are easier to swap. This is why sailors and expedition users spend for marine-grade laminates when they require flexibility.

When Rigid Panels Are the Better Choice

If you have height headroom and want maximum longevity/repairability, rigid framed modules on low-profile mounts remain the default choice; keep flexible modules for stealth builds, curvature, or weight-critical pop-tops.

Costs, Warranties & Where to Buy

Typical Price Ranges (50–430W)

As of Oct 6, 2025, mainstream pricing spans roughly US$130–$400 for 50–200W flexible mono modules (e.g., Renogy 50–200W) and US$600–$1,500+ for premium marine or very high-wattage laminates (e.g., eArc 430W, Solbian SP series). Actuals vary by region and retailer.

Warranty Terms & What They Actually Cover

Read the product (materials) vs performance (power) terms: flexible modules often list 2–5 years product warranty (Solbian AIO example) and longer performance coverage; Sunman’s eArc line lists up to 10-year product on some models. Keep install practices compliant, or coverage can be voided.

Retailers & Authenticity Checks

Buy from the manufacturer or authorized partners to protect warranty (e.g., SunPower enforces authorized-partner sales in many regions). Keep invoices, serials, and photos of your install for any future claim.

Frequent Aluminum Foil Recycling Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.