Energy Chain for a Solar Panel

Written by Admin | June 22, 2025

What Is the “Energy Chain” in a Solar PV System?

Definition and Scope

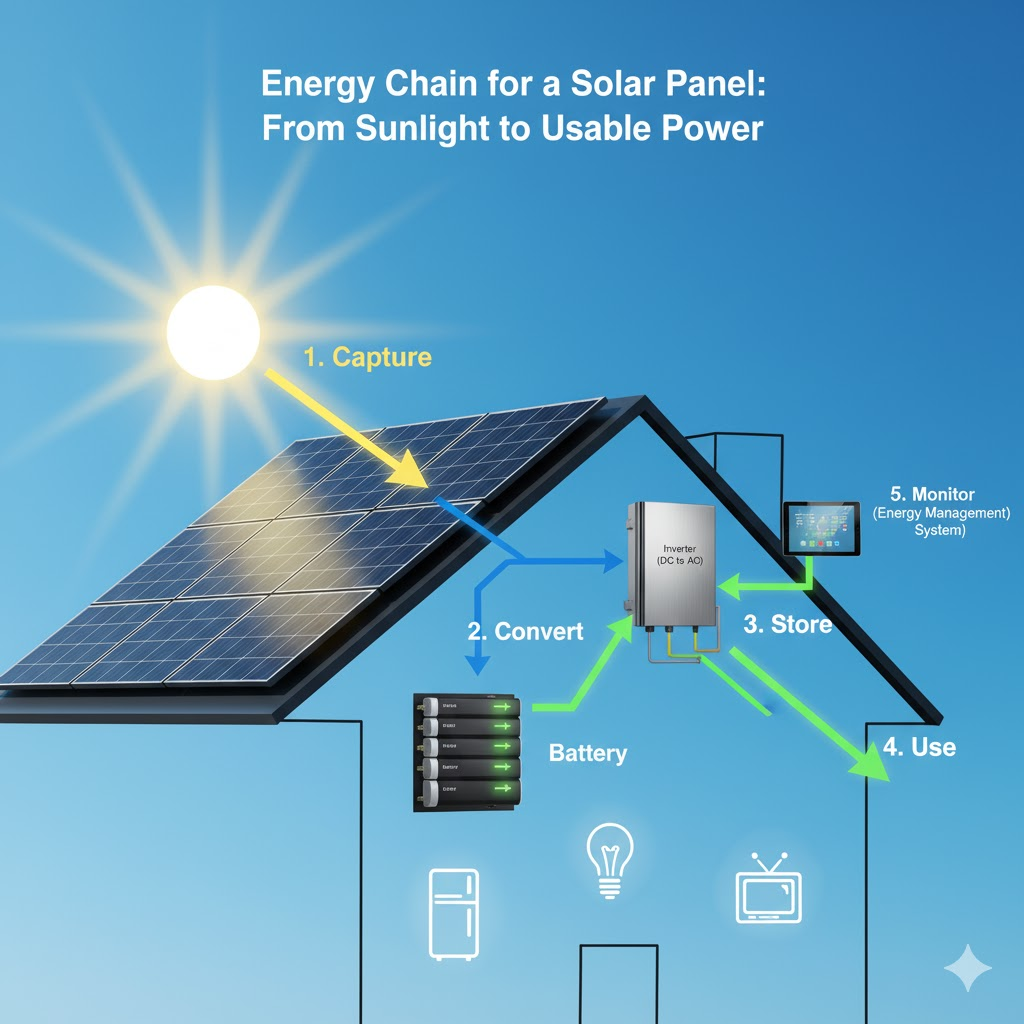

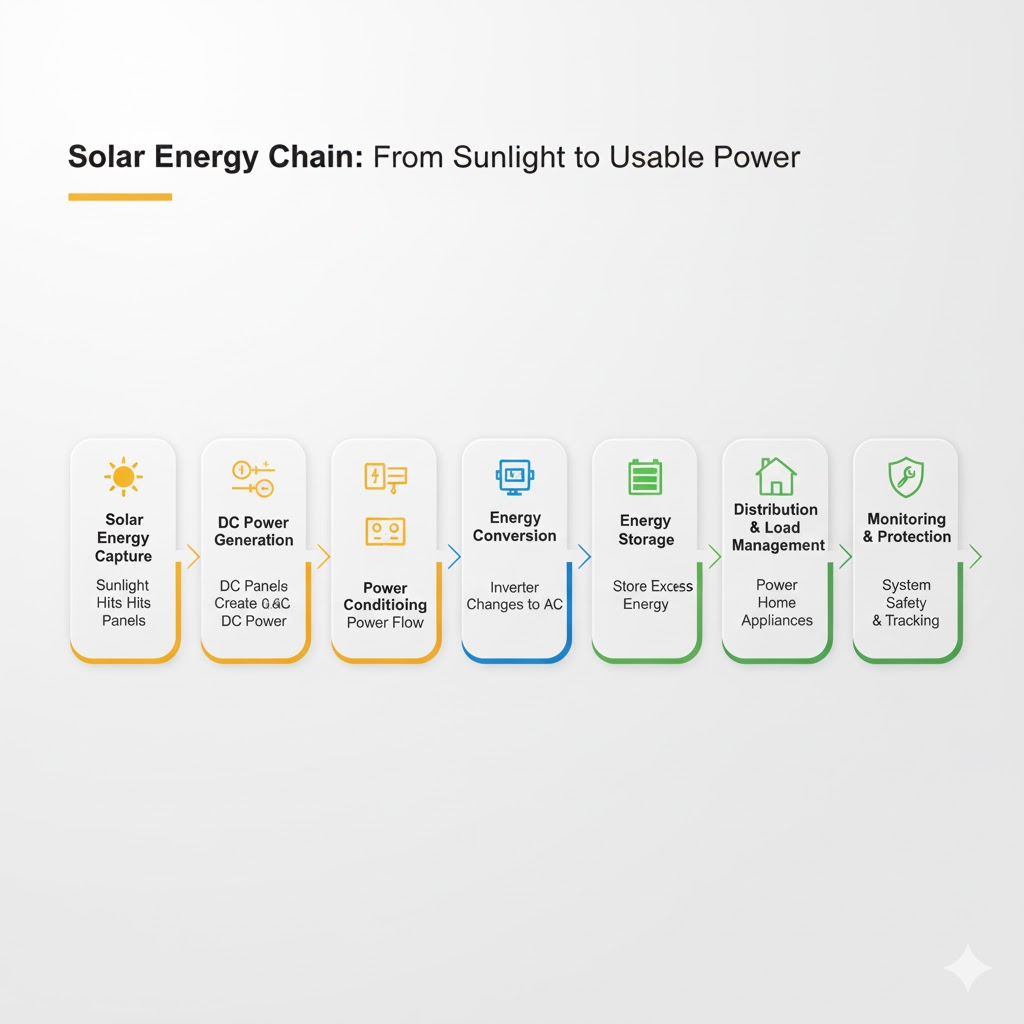

The energy chain is the end-to-end path that sunlight follows to become safe, useful electricity. It starts with photons hitting a photovoltaic (PV) module, continues through direct-current (DC) generation and power conditioning, passes through conversion to alternating current (AC), may include storage in batteries, and ends with distribution to your appliances—monitored and protected the whole way. Think of it as the “journey of a joule,” from sky to socket.

Energy Chain vs. Supply Chain (Key Differences)

- Energy chain = technical flow of energy inside your system (capture → convert → store → use → monitor/protect).

- Supply chain = how hardware is made and moved (polysilicon → ingots/wafers → cells → modules; plus inverters, batteries, logistics). Globally, those manufacturing stages are highly concentrated in a few regions, which matters for availability and price but is distinct from how energy flows through your system.

Stages of the Solar Energy Chain (Overview)

Solar Energy Capture (PV Modules & Irradiance)

PV modules absorb sunlight and create charge carriers. Output depends on irradiance (sunlight intensity), module efficiency, and local conditions like shading or soiling. Even light debris can drop production, which is why site design and upkeep matter.

DC Generation & Module Wiring (Series/Parallel, Combiner Boxes)

Cells are wired into modules; modules are wired in series to raise voltage and in parallel to raise current. Strings land in combiner boxes with fusing before heading to the inverter—keeping currents within safe limits and simplifying maintenance. (Good design reduces mismatch and voltage-drop losses.)

Power Conditioning (MPPT Controllers/Optimizers)

Maximum Power Point Tracking (MPPT) continually adjusts voltage/current to extract the most watts as light and temperature change. MPPT can live inside charge controllers (DC systems) or inside inverters/optimizers (AC systems).

Energy Conversion (Inverters: String, Micro, Hybrid)

Inverters turn DC into grid-quality AC. Choices include string inverters, microinverters (one per module), and hybrid inverters that also manage batteries. Selection affects efficiency, shade tolerance, and monitoring granularity.

Energy Storage (Battery Types & BMS)

Batteries capture surplus solar for nights and outages. LiFePO₄ (lithium iron phosphate) offers long cycle life and stability; lead-acid is lower cost but heavier with shorter life. A Battery Management System (BMS) handles cell balancing and safety limits (voltage, current, temperature).

Distribution & Load Management (AC/DC Loads, Smart Controls)

After inversion, power flows through panels/boards to your home circuits. Smart meters and home energy management can schedule flexible loads (e.g., water heating) to align with solar peaks—raising self-consumption and saving money.

Monitoring, Protection & Safety (Meters, Disconnects, Surge Protection, Rapid Shutdown)

Modern systems log per-module data and alert you to faults. Safety includes DC/AC disconnects, overcurrent protection, and rapid shutdown on buildings so conductors drop to safe voltage quickly for first responders.

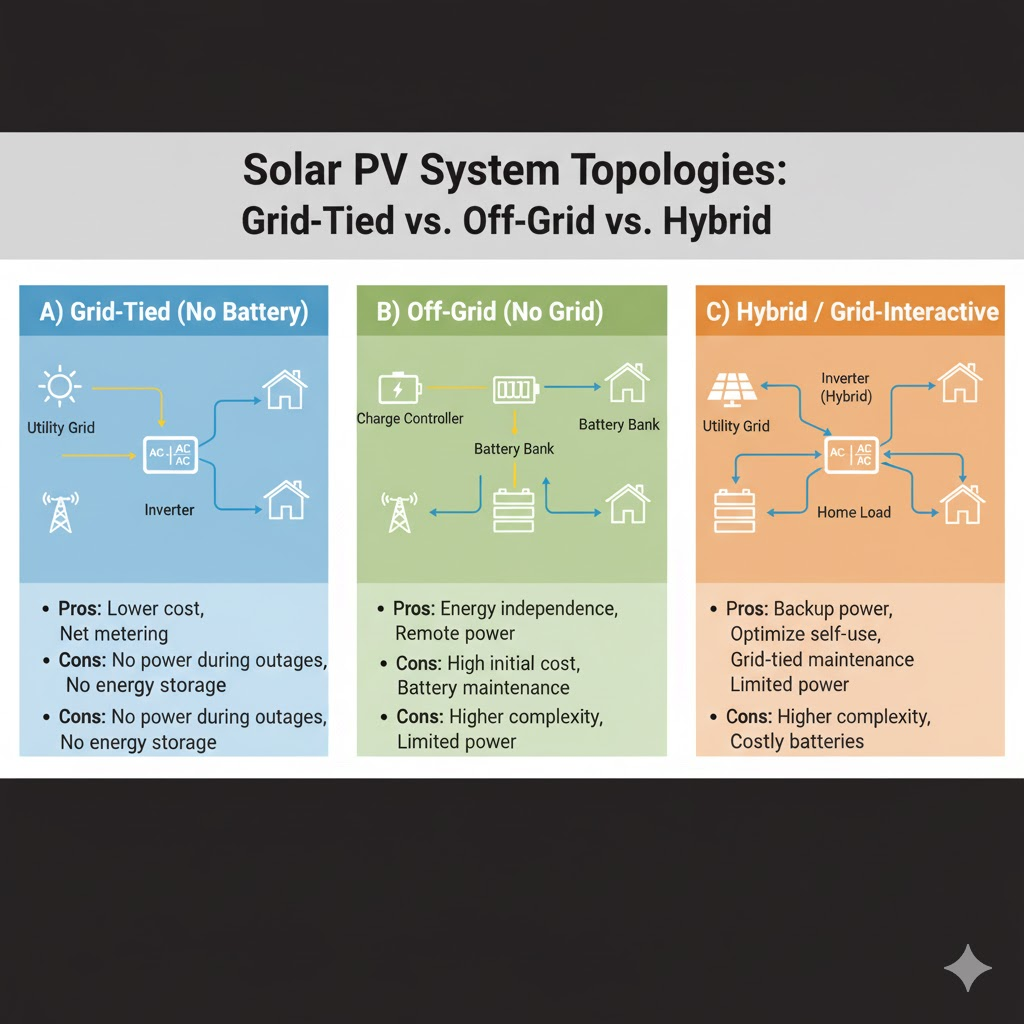

System Topologies Along the Energy Chain

Grid-Tied (No Battery)

String Inverter Architecture

One inverter handles an entire string/array. It’s cost-effective, efficient, and ideal for unshaded roofs with uniform module orientation. Shade on one module can affect the string unless mitigated.

Microinverters & DC Optimizers

Microinverters convert at each module—great for complex roofs and partial shade, with module-level monitoring. Optimizers keep DC but add module-level MPPT, feeding a central inverter. Both strategies improve energy harvest where conditions vary.

Off-Grid

Charge Controller + Battery + Inverter Stack

Off-grid stacks use a charge controller (MPPT) to charge batteries efficiently, then a standalone inverter to supply AC. Design centers on days of autonomy and careful load planning so lights stay on when the weather doesn’t cooperate.

Hybrid/Grid-Interactive with Storage

Hybrid systems do self-consumption, backup, and grid services (export, time-of-use shifting). They can participate in virtual power plants (VPPs) where many homes act together to support the grid—often for payment.

Key Components in the Energy Chain

PV Modules & Ratings (STC/PTC, Temperature Coefficient)

Manufacturers rate modules at STC: 1000 W/m² irradiance, 25 °C cell temperature, AM1.5 spectrum—great for comparisons, not a weather forecast. PTC is a more “real-world” rating (1000 W/m², 20 °C ambient, ~1 m/s wind) and tends to be lower than STC. Modules also list a temperature coefficient (e.g., −0.3% to −0.5%/°C), showing how heat reduces power—important for hot climates.

Mounting & Tracking Systems

Fixed-tilt racks minimize cost and complexity; trackers rotate to follow the sun, raising yield (especially at low latitudes) but adding moving parts and cabling management—often handled with dedicated cable-carrier energy chains on tracker rows.

DC Balance of System (Wiring, Fuses/Breakers, Connectors, Grounding)

Correct conductor sizing, proper connectors, overcurrent protection, grounding, and minimized voltage drop keep DC runs efficient and safe.

MPPT Charge Controllers

For battery-based systems, MPPT controllers convert higher PV voltages down to battery voltage while maximizing harvest—essential in off-grid and hybrid stacks.

Inverters (Efficiency, Surge Handling, THD)

Look for CEC/Euro efficiency in the upper 90s and low total harmonic distortion (THD). Hybrids should list surge/overload capability for starting motors and managing brief peaks.

Batteries (LiFePO₄ vs Lead-Acid; DoD, Cycle Life)

LiFePO₄ supports deeper depth of discharge (DoD) and higher cycle life than lead-acid, with better round-trip efficiency. Always confirm the usable kWh at your intended DoD and temperature range, and ensure the BMS is compatible with your inverter.

Energy Management & Monitoring (EMS, Data Logging)

Whole-home EMS platforms coordinate PV, storage, EV charging, and flexible loads. Forecast-aware control (using weather and irradiance models) can pre-charge or pre-cool to ride through peaks gracefully.

Performance & Efficiency Factors

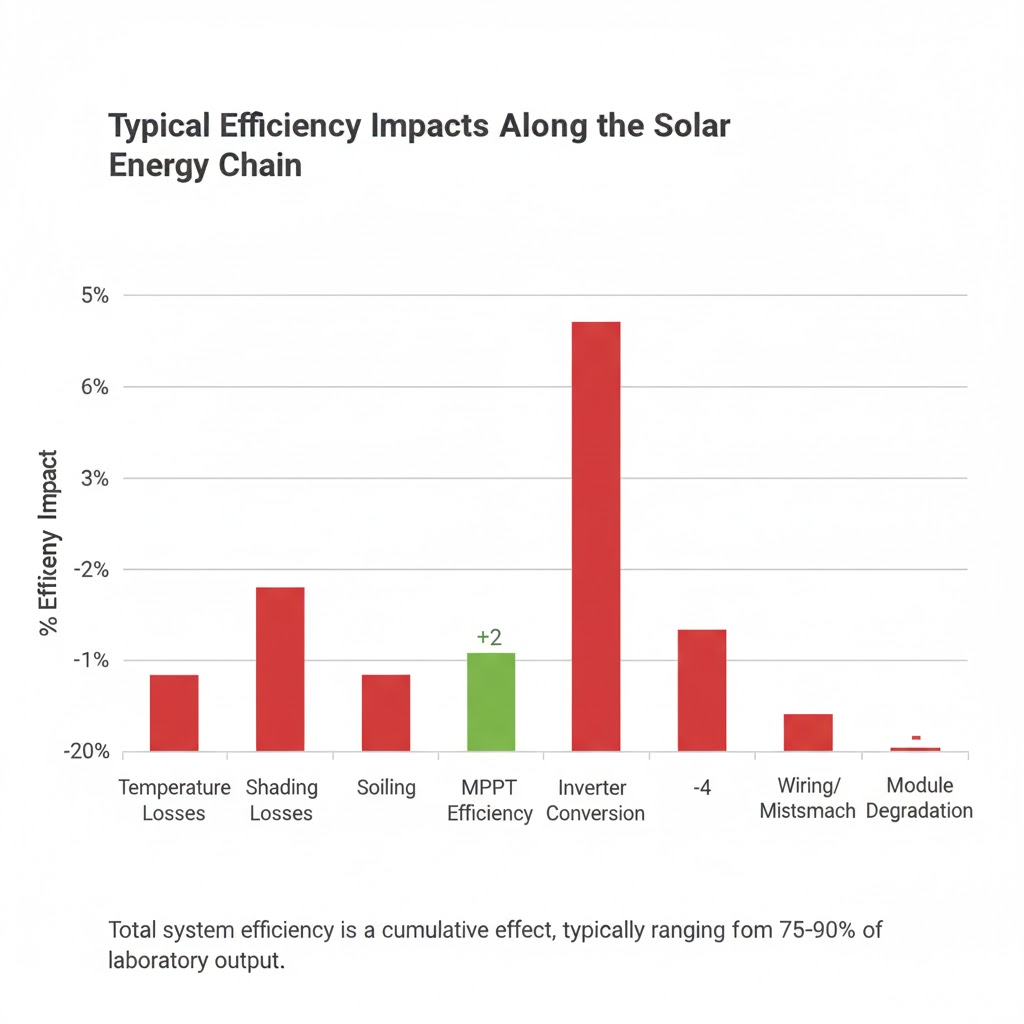

Temperature, Shading, and Soiling Losses

Heat lowers voltage, shade reduces current, and dust attenuates light; together they can cut output noticeably without good design and maintenance.

Orientation, Tilt, and Tracking Gains

Panel azimuth and tilt shape the daily/seasonal profile. Trackers can add significant yield where the economics pencil out; fixed-tilt remains simplest for most rooftops.

MPPT & Inverter Conversion Efficiency

Well-implemented MPPT plus a high-efficiency inverter recovers energy that would otherwise be lost to sub-optimal operating points and conversion.

Wiring/Voltage-Drop and Mismatch Losses

Correct stringing, conductor sizing, and layout minimize resistive losses and mismatch between modules.

Sizing the Energy Chain

Load Profiling and Daily kWh Target

Inventory your appliances and hours of use to set a daily kWh target. Prioritize flexible loads you can time-shift (washing, EV charging, water heating).

Panel, Inverter, and Battery Sizing Rules of Thumb

- Panels: size DC to meet your daily kWh at local sun hours, with a margin for seasons and losses.

- Inverter: AC rating roughly near (or a bit below) DC array size for grid-tie; include surge/backup needs for hybrids.

- Battery: usable kWh ≈ evening/night load + desired backup window. Off-grid systems often plan for several days of autonomy.

Autonomy, Reserve Days, and Depth of Discharge

Set reserve days based on weather variability and your tolerance for generator/grid reliance; choose DoD to balance runtime vs. battery life.

Using Solar Power for Heating Loads (Water/Space Heating Reality Check)

Direct Electric Resistance vs Heat Pumps

For electric heating, heat pumps move 2–4× more heat per kWh than resistance coils (higher COP), meaning far less PV and battery are needed to stay comfortable. It’s one of the easiest wins in an all-electric home.

When DC or Thermal Solar Is More Appropriate

For domestic hot water, dedicated heat-pump water heaters (or solar thermal in some contexts) can beat resistive elements powered by PV, especially where space and budgets are tight.

Costs & Economics of the Energy Chain

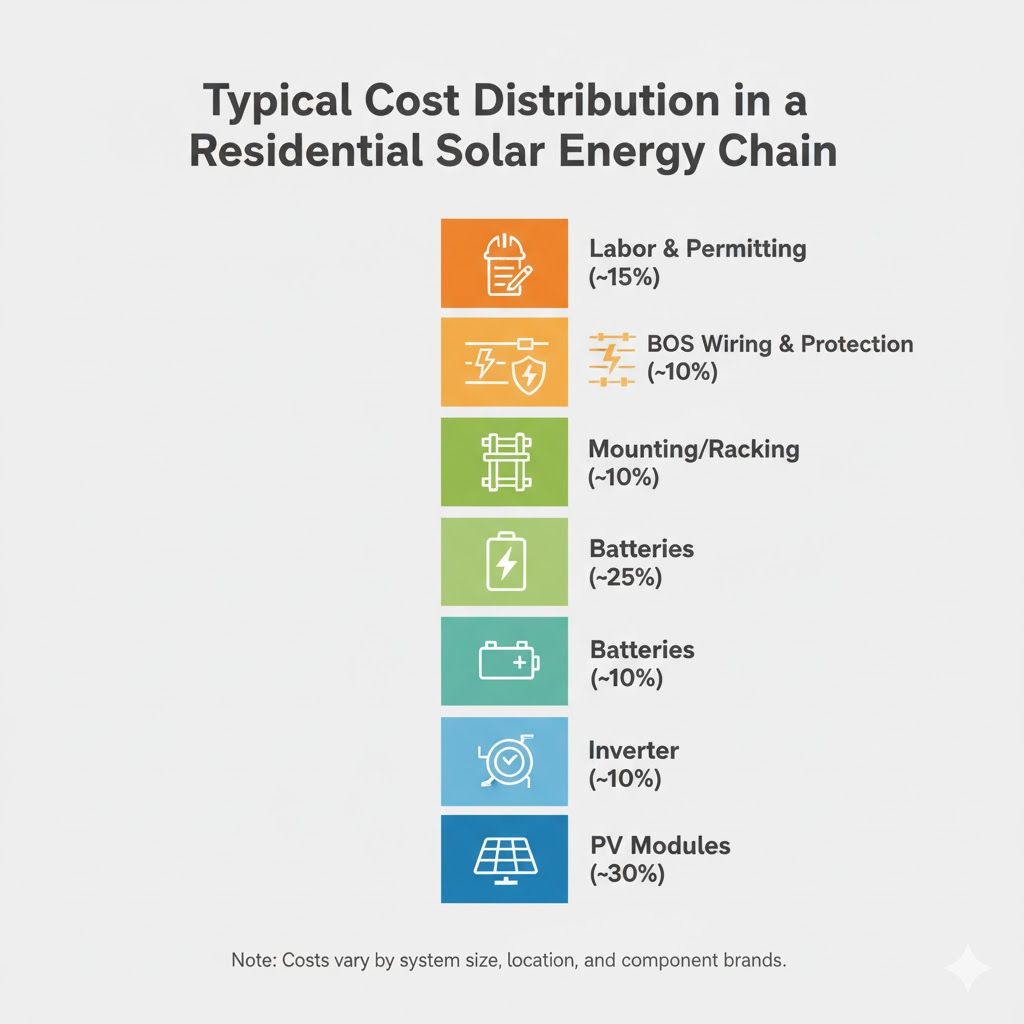

Equipment, Installation, and O&M Costs

Total cost spans modules, inverters, racking, BOS wiring/protection, labor, permitting, and optional storage. U.S. benchmarks are tracked annually by NREL and vary by market, scale, and component choices.

Incentives, LCOE, and Payback Considerations

Tax credits, rebates, and net-metering/exports policies shape payback. Comparing levelized cost of energy (LCOE) to local tariffs (including time-of-use) clarifies whether to export or self-consume more with storage.

Reliability, Safety & Compliance

Electrical Codes and Standards (e.g., NEC 690, Rapid Shutdown)

On buildings, NEC 690.12 requires rapid shutdown: conductors outside the array boundary must drop below 30 V within 30 s; inside the boundary, ≤ 80 V within 30 s (with exceptions such as some canopies/ground mounts in 2023 NEC). Labeling and initiation rules also apply.

Protection Devices, Fire Safety, and Anti-Islanding

Inverters certified to IEEE 1547/UL 1741 must anti-island, i.e., stop energizing the grid during outages to protect line workers. Proper overcurrent, surge, and grounding practices reduce electrical and fire risk.

Weatherization and Environmental Hardening

Seal penetrations, specify appropriate corrosion resistance and wind/snow ratings, and choose enclosures to match your site’s climate.

Environmental & End-of-Life Impact

Lifecycle Footprint and Recycling/Take-Back Programs

PV’s life-cycle emissions are low vs. fossil power, and module recycling is scaling. A landmark IRENA/IEA-PVPS study estimates up to ~78 million tonnes of recoverable material by 2050—an emerging circular-economy opportunity.

Future Innovations Affecting the Energy Chain

Perovskite-Silicon Tandems and Higher-Efficiency Modules

Tandem modules that stack perovskite over silicon are moving from pilot to early commercial shipments, with reported module efficiencies above today’s mainstream silicon—promising more energy from the same roof area.

Grid-Forming Inverters, VPPs, and AI-Based Forecasting

Grid-forming inverters can set voltage/frequency and support black-start, helping the grid host more renewables. At the edge, VPPs aggregate millions of small systems (PV, batteries, EVs) to act like a flexible power plant. Forecast-driven controls and AI sharpen when to store, export, or pre-heat/cool.

Second-Life/Advanced Batteries and Smart Load Orchestration

Second-life EV batteries and new chemistries could cut costs, while smarter orchestration will make homes feel seamless—quiet resilience you can actually feel when the lights stay on.

Alternate Meanings to Capture Search Intent

Solar Panel Supply Chain (Manufacturing to Installation) at a Glance

Polysilicon → Ingots/Wafers → Cells → Modules

These are the five classic manufacturing stages; diversification and policy shape where each happens.

Inverters, Batteries, Glass/Backsheet, and Logistics

Balance-of-system components and shipping/warehousing complete the picture and influence prices and lead times.

Cable-Carrier “Energy Chains” for Solar Trackers (Cable Management)

On single-axis trackers, energy-chain cable carriers guide and protect moving DC/communication cables—preventing fatigue and abrasion as rows pivot daily. world—one small action at a time.

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.