Home » How to Recycle and Reuse Aluminum Foil: Can You Recycle Aluminum Foil?

Propane Leak Detection: How to Find, Monitor, and Prevent Leaks

Written by Admin | June 22, 2025

What Is Propane & Why Leaks Are Dangerous

Key properties of propane (heavier than air, flammability)

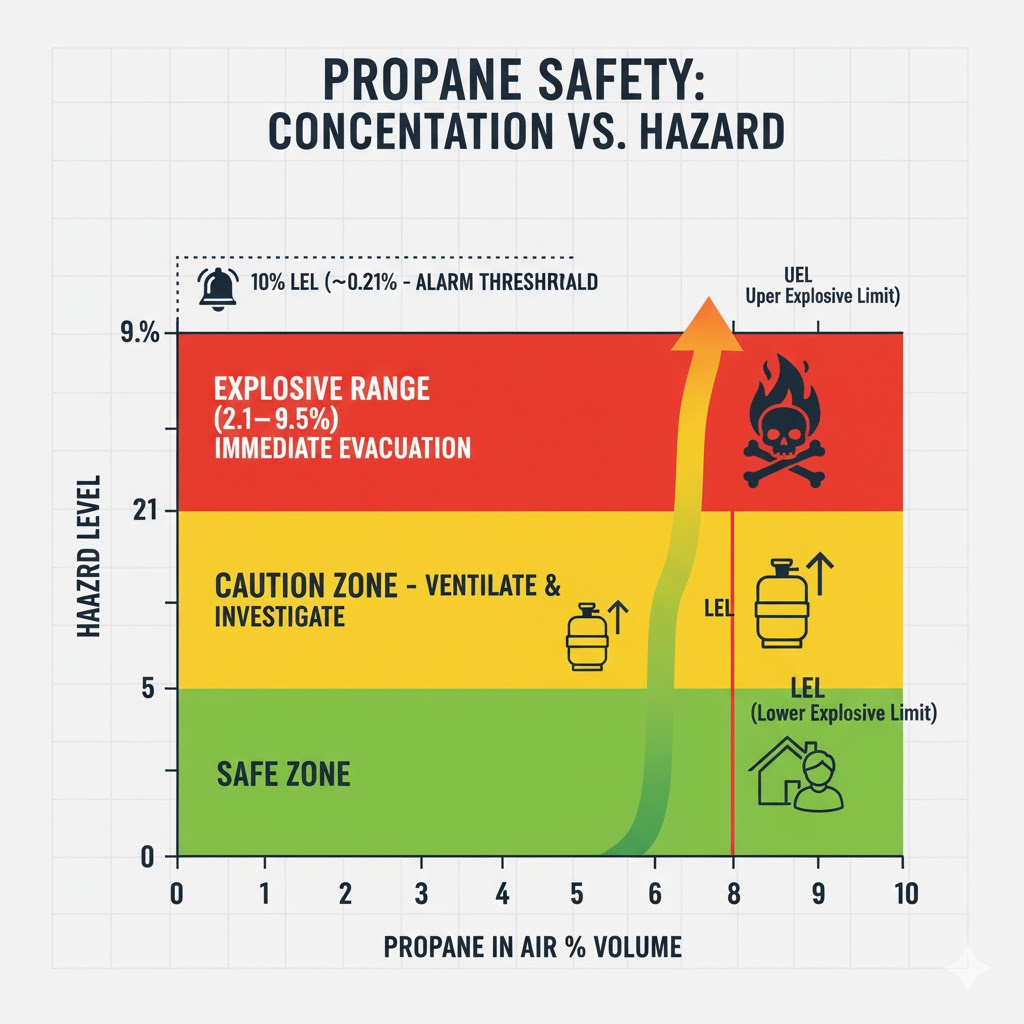

Propane is a colorless, naturally odorless hydrocarbon stored as a pressurized liquid that vaporizes when released. In air, it’s heavier than the surrounding atmosphere (relative gas density ~1.55), so leaked propane tends to sink and pool in low spots like basements, crawlspaces, pits, and floor-level recesses. Its flammable (explosive) range in air is roughly 2.1%–9.5% by volume, which means even small accumulations can reach burnable concentrations if an ignition source is present.

To make leaks easier to notice, suppliers add a strong-smelling odorant (commonly ethyl mercaptan). Because heavy gases can stratify in still air, the odor may be stronger at lower levels—another reason to check low-lying areas carefully when investigating a suspected leak.

Plain-language glossary (for clarity)

• LEL / UEL: Lower/Upper Explosive Limit—the range of gas in air that can ignite.

• 10% LEL: A safety threshold used by alarms; for propane that’s ~0.21% propane in air.

• Ethyl mercaptan: The rotten-egg odorant added to propane so leaks are easier to smell.

• R290 vs LP-Gas: R290 is propane used as a refrigerant; LP-Gas/propane is used as a fuel—different rules and detectors may apply.

• Bump test vs calibration: A quick gas exposure to prove the sensor alarms (bump) vs. adjusting the instrument to a known gas standard (calibration).

Fire, explosion, and health risks

When propane accumulates within the flammable range and meets a spark, static discharge, pilot flame, or hot surface, it can ignite explosively. At high concentrations, propane can also displace oxygen and lead to dizziness, confusion, or asphyxiation; contact with the cold liquid can cause frostbite. Safety agencies treat atmospheres at or above 10% of the lower explosive limit (LEL) as hazardous.

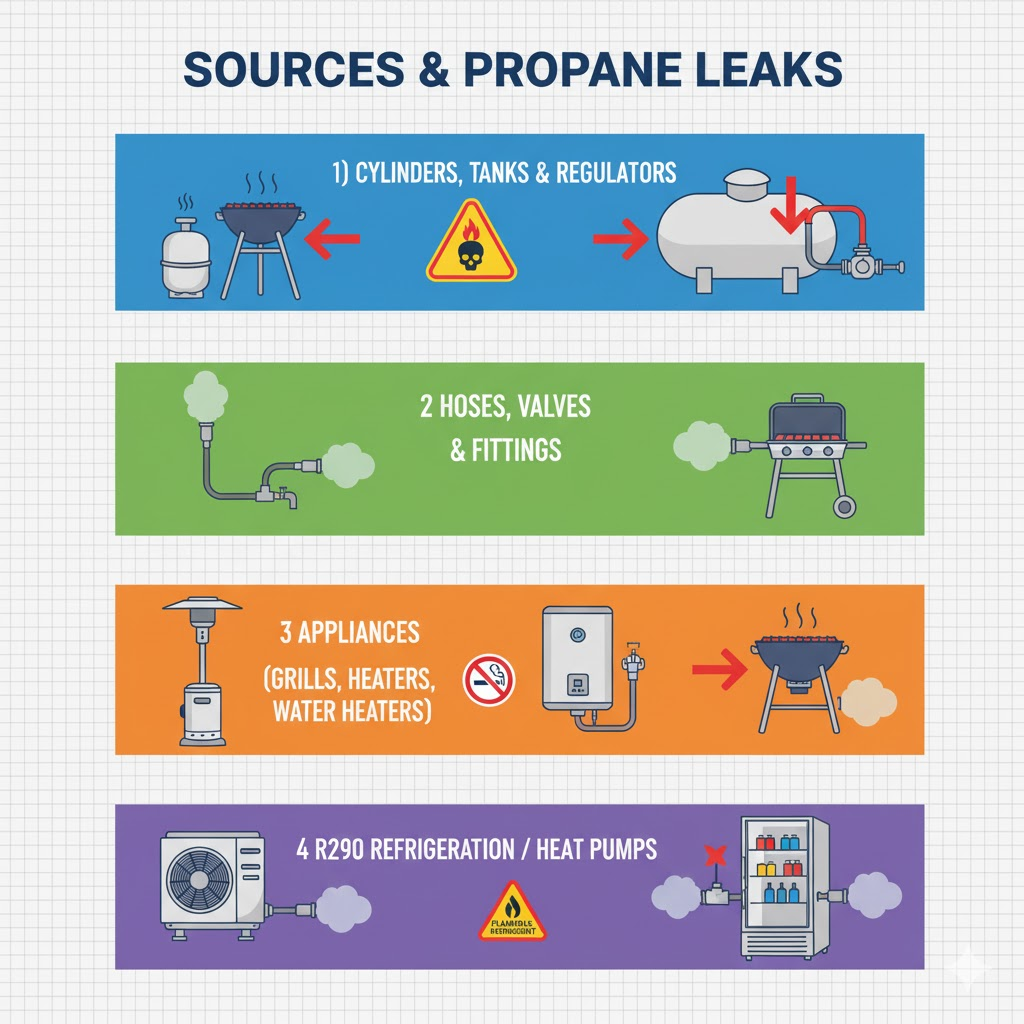

Common Causes of Propane Leaks

Cylinders, tanks, and regulators

Leaks often originate at cylinder/tank valves, service valves, relief valves, or regulator diaphragms—especially after transport, a tank change, or service interruption. Codes require a system leak test following certain events (e.g., new installation, tank change, out-of-gas situations) to verify tightness.

Hoses, valves, and fittings

Mechanical stress, vibration, UV exposure, and thread seal failures can create microleaks at unions, flares, quick connects, and appliance connectors. Routine checks focus on these junctions because most fugitive emissions in fuel and process systems arise from components like valves and connectors.

Appliances (grills, heaters, water heaters)

Appliance manifolds, burner valves, and flexible connectors can loosen during seasonal storage or cleaning. After any appliance service or reconnection, a compliant leak test is recommended before returning the system to use.

Refrigeration and heat pumps using R290

Propane (R290) used as a refrigerant has different safety controls from propane used as a fuel. Refrigeration standards (e.g., ASHRAE 15; EN 378 in Europe) address refrigerant leak detection, ventilation, and equipment interlocks in machinery rooms and occupied spaces. These frameworks require detectors to actuate alarms and ventilation in locations where leaked refrigerant would concentrate.

Signs You May Have a Propane Leak

Odorant (rotten-egg smell) and hissing sounds

A sulfur/“rotten-egg” odor—added for safety—is the most common warning sign. Hissing or whistling near a tank, regulator, or piping can indicate gas escaping under pressure.

Dead vegetation, frost on components, bubbles

Unexplained dead grass or plants along an underground line, visible frost/ice on a valve or fitting (from rapid cooling during a leak), or bubbling in standing water above buried piping are visual red flags.

Usage spikes or poor appliance performance

Sudden propane consumption spikes or weak/small flames from appliances may point to a leak or connection issue that warrants inspection.

What To Do If You Suspect a Leak (Immediate Safety Steps)

Shut off fuel and evacuate; avoid ignition sources

If you suspect a leak, do not use lights, phones, or any device that could spark. Extinguish open flames and evacuate people and pets. If it’s safe, close the cylinder or tank service valve by turning it clockwise.

Call your propane supplier/emergency services

From a safe location, contact your propane supplier or local fire department. Do not re-enter until a qualified professional confirms the area is safe and repairs are made.

DIY Leak Check: Bubble (Soap) Test — Step-by-Step

When to use it and where to apply

A bubble test is a simple screening method for above-ground connections (e.g., cylinder-to-regulator, appliance connectors) when there’s no active emergency. Do this after a tank change, seasonal restart, or anytime fittings are disturbed, focusing on joints, valves, and regulator interfaces.

Use a listed, non-corrosive leak-detector solution

Apply a commercial leak-detector (e.g., Snoop®) or a thick dish-soap solution to suspected joints; growing bubbles reveal a leak. Note that some soaps can be mildly corrosive, so commercial solutions are preferred for routine checks. If bubbles persist after tightening, stop and call a pro.

(Visual aid suggestion: 3 small images—“Shut off → Apply solution → Observe bubbles.”)

Professional Leak Detection Methods

Pressure/leak checks (code-compliant)

Fuel gas codes require specific leak/pressure tests after installation, service interruption, or certain repairs to verify system integrity before placing appliances back in service. These tests use calibrated gauges/manometers and approved gases (never oxygen).

Electronic sniffers and LDAR programs

Professionals use electronic combustible-gas detectors (portable or fixed) and, in industrial settings, LDAR (Leak Detection and Repair) programs guided by EPA Method 21 or optical gas imaging to catch fugitive emissions from valves, flanges, and pumps.

Advanced (for facilities & pros)

• Setpoints: Use a warning threshold (e.g., 10% LEL) for alerts and an alarm threshold (e.g., 20–25% LEL) for actions like ventilation/startup interlocks—follow your AHJ and manufacturer.

• Calibration gas: Use certified propane mix at relevant %LEL/ppm; adjust intervals for harsh or high-solvent environments.

• Methods: OGI is great for rapid surveys outdoors; Method 21 is precise for components; ultrasonic sensors shine around high-pressure gas.

• Compliance: Distinguish UL/CSA listings (North America) vs ATEX/IECEx (EU/International) for hazardous areas.

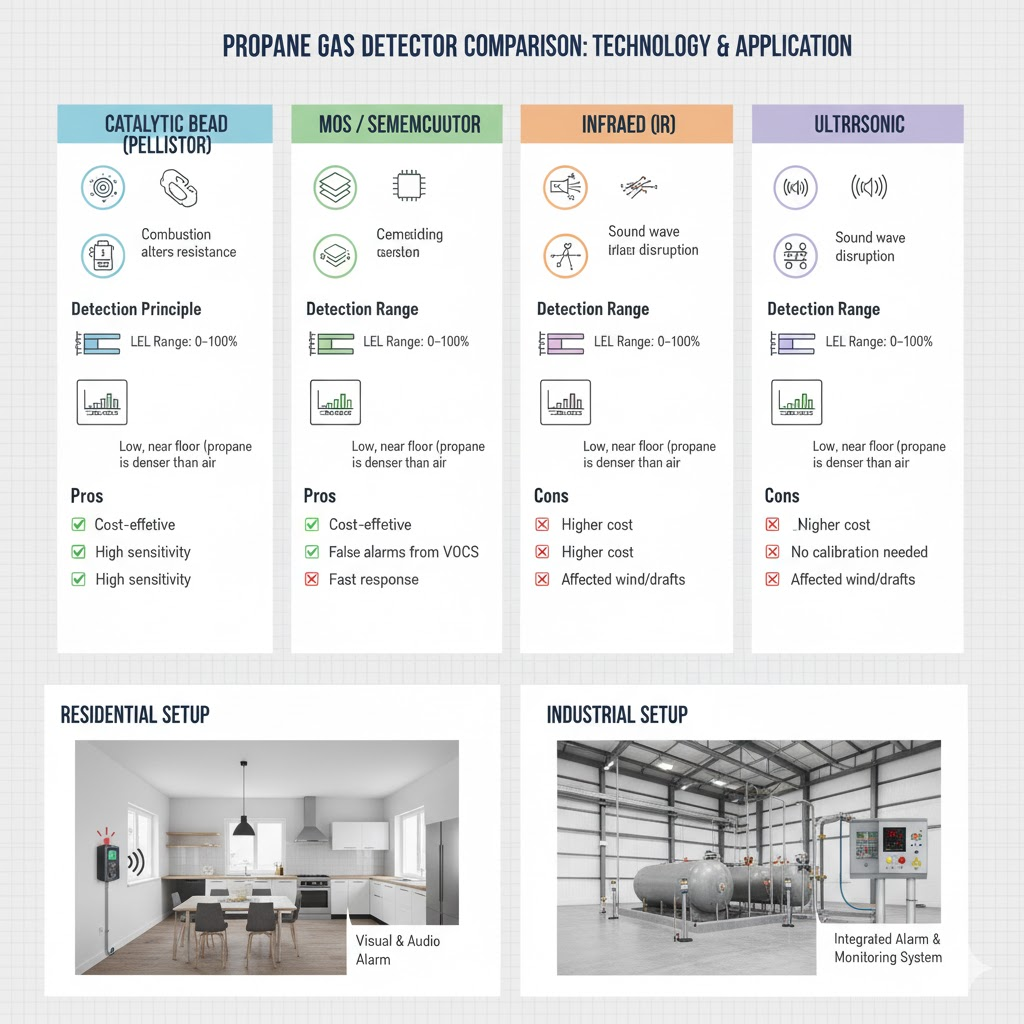

Propane Gas Detectors: Types & How They Work

How it works (simple): Detectors sample the air near potential leak points. When propane reaches the device’s set threshold (often referenced to %LEL), it triggers an audible/visual alarm and, in some systems, ventilation or equipment shutdown.

Catalytic bead (LEL), MOS/semiconductor, infrared, ultrasonic

Catalytic bead (pellistor): Measures heat from oxidizing gas on a catalyst—robust and common for %LEL combustible detection.

MOS/semiconductor: Senses resistance change on heated metal-oxide; sensitive at low ppm but can be influenced by humidity/contaminants.

Infrared (IR): Detects hydrocarbon absorption of IR light; stable, fast, and not oxygen-dependent, but requires gas-specific calibration curves.

Ultrasonic (for high-pressure leaks): Listens for the ultrasonic signature of pressurized gas escaping, useful outdoors or in ventilated spaces.

At a glance (benefits & examples):

• Catalytic: Low cost, good for general %LEL monitoring; needs oxygen; avoid silicone poisoning.

• MOS: Good sensitivity for “sniffing” small leaks; may drift with humidity—ideal for quick checks around fittings.

• IR: Stable baseline, fast response, not O₂-dependent—excellent in mechanical rooms or fixed systems.

• Ultrasonic: Detects leaks even when wind disperses gas—great in open industrial areas with high-pressure lines.

Stand-alone vs. interconnected/monitored systems

Residential fuel-gas alarms can be single-station (local sounder) or part of interconnected, monitored systems that can notify occupants and central stations. Newer codes clarify placement and performance for both approaches.

Propane vs. natural gas detectors (sensor & placement differences)

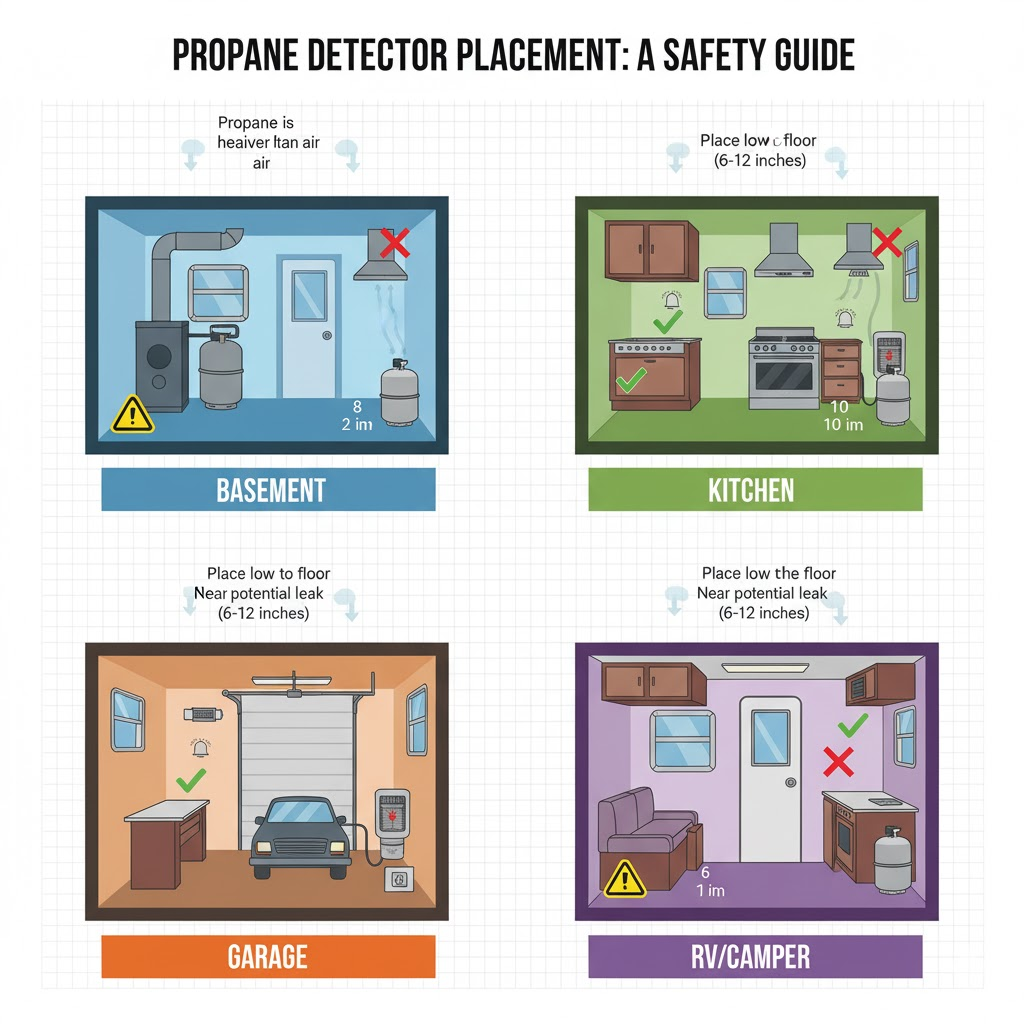

Detectors should be calibrated to the target gas for accurate alarms; sensor responses vary by gas species. Because propane sinks, propane detectors are installed low, while methane (natural gas) detectors are installed high. Always follow the device’s listing and installation manual.

Alarm Thresholds & LEL Basics for Propane

What “10% LEL” means and why it’s used

LEL is the minimum concentration that can ignite. For propane, LEL ≈ 2.1% by volume; 10% LEL equals ~0.21% propane in air. Many safety programs and confined-space rules treat ≥10% LEL as a hazardous atmosphere requiring immediate action—hence many detectors alarm at or below this point.

Where to Install Propane Gas Detectors

Mounting height (place low because propane sinks)

Install propane detectors near the floor (often within 6–12 inches of the finished floor) or per the manufacturer’s instructions; avoid corners or dead-air pockets where gas may not circulate.

Distance from appliances, vents, and dead-air spaces

Place sensors where propane would first accumulate and where air currents won’t dilute the sample (away from supply vents, windows, or fans). Position relative to likely leak sources (tanks, regulators, appliance connectors) according to the manufacturer and applicable standards.

Rooms/zones to cover (kitchens, basements, garages, RVs/boats)

Prioritize spaces with propane appliances or storage (kitchens, utility rooms, basements/garages, mechanical rooms) and enclosed mobile spaces like RVs and boats. Follow residential alarm guidance set out in NFPA 715 and the detector’s listing.

(Visual aid suggestion: one diagram showing propane detectors low vs methane detectors high.)

Installation & Commissioning Best Practices

Power options (plug-in, hardwired, battery) and backup

Choose UL-listed residential fuel gas alarms appropriate for your dwelling (plug-in with backup, hardwired with battery, or battery-only). Confirm the listing (e.g., UL 1484 for residential fuel-gas alarms) and install per instructions for that power type.

Avoiding false alarms (humidity, aerosols, airflow)

Aerosols, silicone vapors, solvents, and extreme humidity/condensation can affect some sensors. Keep units clean, avoid installing directly in steamy or drafty spots, and follow manufacturer placement notes to limit nuisance alarms.

Troubleshooting (quick help)

• Frequent alarms near kitchen/bath: Move unit away from steam, sprays, and strong airflow; check for silicone aerosols.

• Detector won’t test/beep: Verify power/battery, check end-of-life indicator, and consult the manual.

• False alarms after painting/renovation: Ventilate the area; some fumes can affect sensors temporarily.

• After a nuisance alarm: Inspect placement and nearby chemicals; perform a bump test if recommended.

Testing, Maintenance & Calibration

Monthly tests and sensor life/replacement

Test alarms using the built-in test button monthly (or per the manual) and replace units at end-of-life. In industrial contexts, many manufacturers recommend routine bump tests and periodic calibration; sensor lifespans vary by technology and environment (often ~2–5 years for many sensors).

Annual calibration/bump testing

For fixed/portable detectors used occupationally, safety bulletins commonly call for a bump test before each day’s use (portable) and scheduled calibration intervals—adjusted for harsh conditions or suspected sensor poisoning.

Codes, Standards & Certifications

NFPA 715 (residential fuel gas alarms)

NFPA 715 (2023) is the first dedicated standard for installing residential fuel-gas alarms (natural gas, propane/LP-Gas), covering selection, placement, performance, notification, and maintenance for single- and multiple-station systems.

NFPA 58 (LP-Gas) and NFPA 54 (Fuel Gas Code)

NFPA 58 governs LP-Gas storage, handling, and equipment; NFPA 54 (National Fuel Gas Code) covers installation of fuel-gas piping and appliances, including leak/pressure test requirements after installation or service interruptions.

UL 1484 / UL 2075 listings and 10% LEL criteria

UL 1484 is the U.S. product safety standard for residential fuel-gas alarms intended to detect propane and natural gas; UL 2075 covers gas and vapor detectors/sensors used in system applications (often commercial/industrial). Alarm set points reference LEL percentages defined in codes and product standards.

ASHRAE 15 / UL 60335-2-40 for R290 refrigeration systems

ASHRAE 15 sets refrigeration safety requirements, including when refrigerant leak detection must trigger alarms and ventilation; UL 60335-2-40 includes product safety requirements for HVAC equipment (e.g., detection and controls for flammable refrigerants). Local adoption varies—always follow the edition your jurisdiction enforces.

Further reading (authoritative)

• NFPA 715 overview (Residential Fuel Gas Detection)

• NFPA 54 & NFPA 58 overview pages

• ASHRAE 15/15.2 summaries (refrigeration safety)

• Reputable safety organization guidance on LP-Gas

Special Applications: Refrigeration & Heat Pumps Using Propane (R290)

Refrigerant leak detection vs. fuel gas detection

R290 in sealed refrigeration circuits is governed by refrigeration safety rules (ASHRAE 15/34; EN 378), which use refrigerant concentration limits, machinery-room rules, ventilation interlocks, and equipment shutoffs—this is different from fuel-gas alarms used for piping and appliances burning propane.

Machinery rooms, ventilation interlocks, and shutdowns

Where required, detectors in machinery rooms must be placed where leaked refrigerant would collect and must initiate audible/visual alarms and mechanical ventilation (and, where applicable, equipment shutdown) at prescribed thresholds.

Choosing the Right Propane Gas Detector

Certifications, features, connectivity, and alerts

Look for clear listing marks (e.g., UL 1484), audible output (≥85 dB), end-of-life indication, and smart options like interconnection or remote notifications. Match the sensor type to the environment (e.g., IR for stable %LEL monitoring in some fixed systems; MOS for low-ppm sniffing where appropriate).

Placement kits and multi-room strategies

Plan coverage wherever propane could be used or accumulate (appliance rooms, low-lying spaces, enclosed garages/RVs). Use multiple detectors and follow the manufacturer’s spacing and height charts rather than “one-per-house” rules of thumb.

Real-world mini-case (social proof): A homeowner installed two UL-listed propane alarms—one near the basement water heater and one by the garage utility wall. During a seasonal restart, the low-mounted unit near the regulator alerted; a loose connector was tightened and verified with a bubble test. No injuries, no property damage, and a lot of peace of mind.

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.