Rooftop Greenhouse Description

Written by Admin | Nov 20, 2025

What Is a Rooftop Greenhouse?

Core Concept and Scope

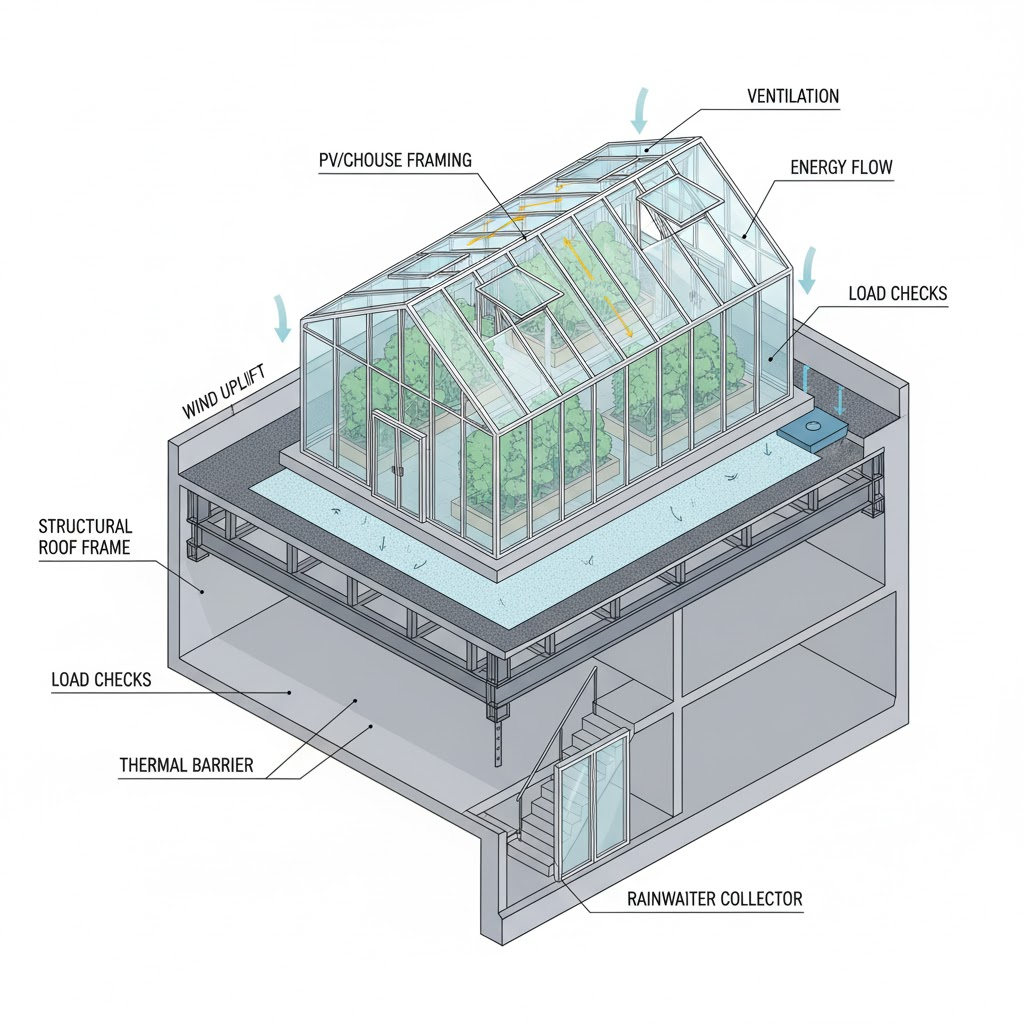

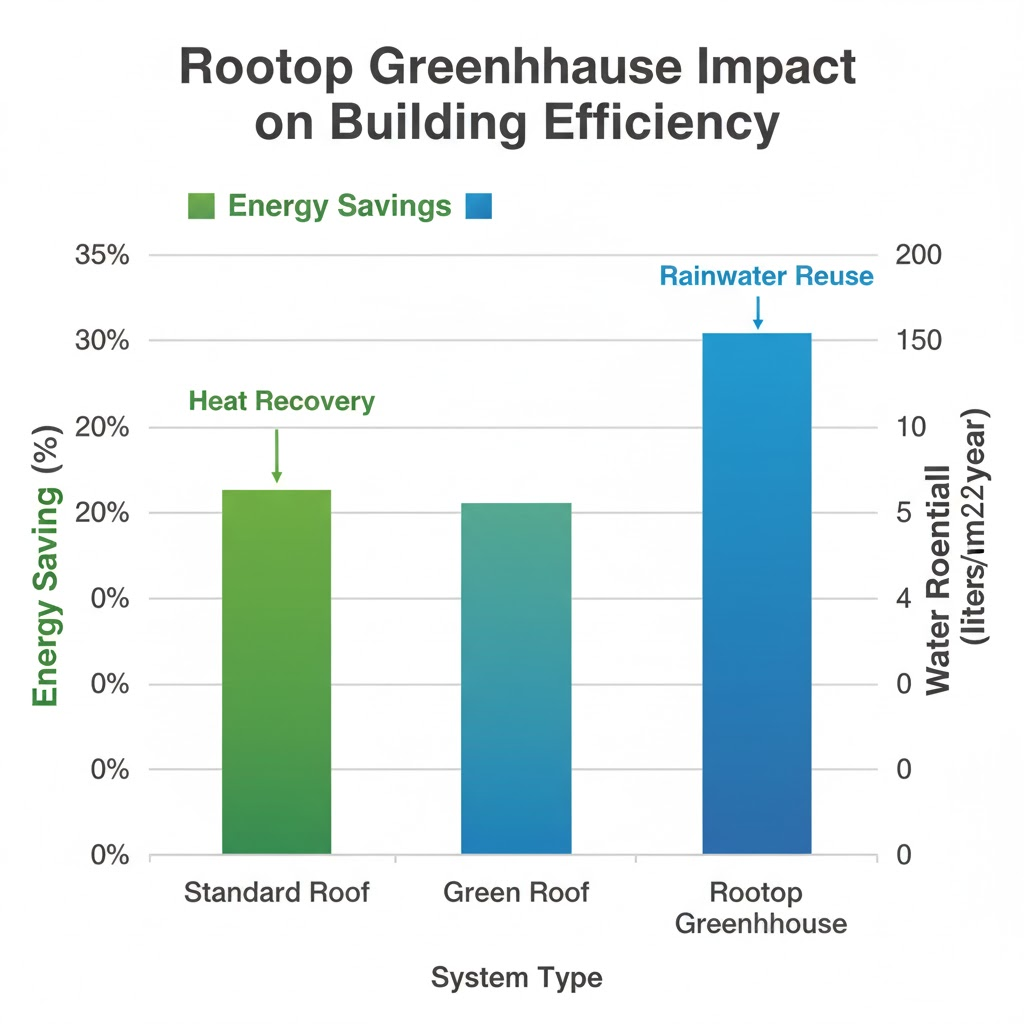

A rooftop greenhouse is a food-growing structure purpose-built on the roof of an existing or new building. Unlike simple green roofs or open rooftop gardens, it’s an enclosed, climate-controlled space designed to produce high-quality crops near consumers while exchanging energy, water, and even CO₂ with the host building. Properly designed, the greenhouse and building “help” each other: the greenhouse can temper the roof, harvest rainwater, and use waste heat; the building benefits from insulation and reduced stormwater runoff. This integrated approach—often called an integrated rooftop greenhouse (i-RTG)—has been shown to improve overall energy performance and resource efficiency.

Relation to Building-Integrated Agriculture (BIA) and Controlled-Environment Agriculture (CEA)

Rooftop greenhouses sit at the intersection of Building-Integrated Agriculture (BIA)—placing food production inside or on buildings—and Controlled-Environment Agriculture (CEA), where climate, light, water, and nutrients are actively managed for consistent yields. In cities, rooftops offer the sunlight, access, and proximity CEA needs, while the building shell supplies structure and potential energy synergies. Reviews of rooftop farming consistently frame rooftop greenhouses as a promising BIA/CEA model for year-round production in dense urban areas.

Quick Glossary (Plain English)

- BIA: Growing food within a building’s envelope (on/inside the structure).

- CEA: Farming with controlled climate, light, water, and nutrients.

- PAR: Plant-usable light (400–700 nm) that drives photosynthesis.

- U-value: How easily heat passes through a material—lower means better insulation.

- OPV: Organic photovoltaics—light, semi-transparent solar panels used as greenhouse shading.

- VPD: Vapor pressure deficit—used to balance plant transpiration and humidity.

- Wind uplift: Suction forces that can lift roof elements in strong winds.

How It Works (3 Steps)

- Capture & condition light: Sunlight provides most energy for growth; glazing and shading tune quality and intensity.

- Control the microclimate: Heating/cooling, humidity, CO₂, and irrigation are managed for target crops.

- Exchange with the building: Waste heat, rainwater, and sometimes CO₂ are shared to save energy and water.

Key Benefits

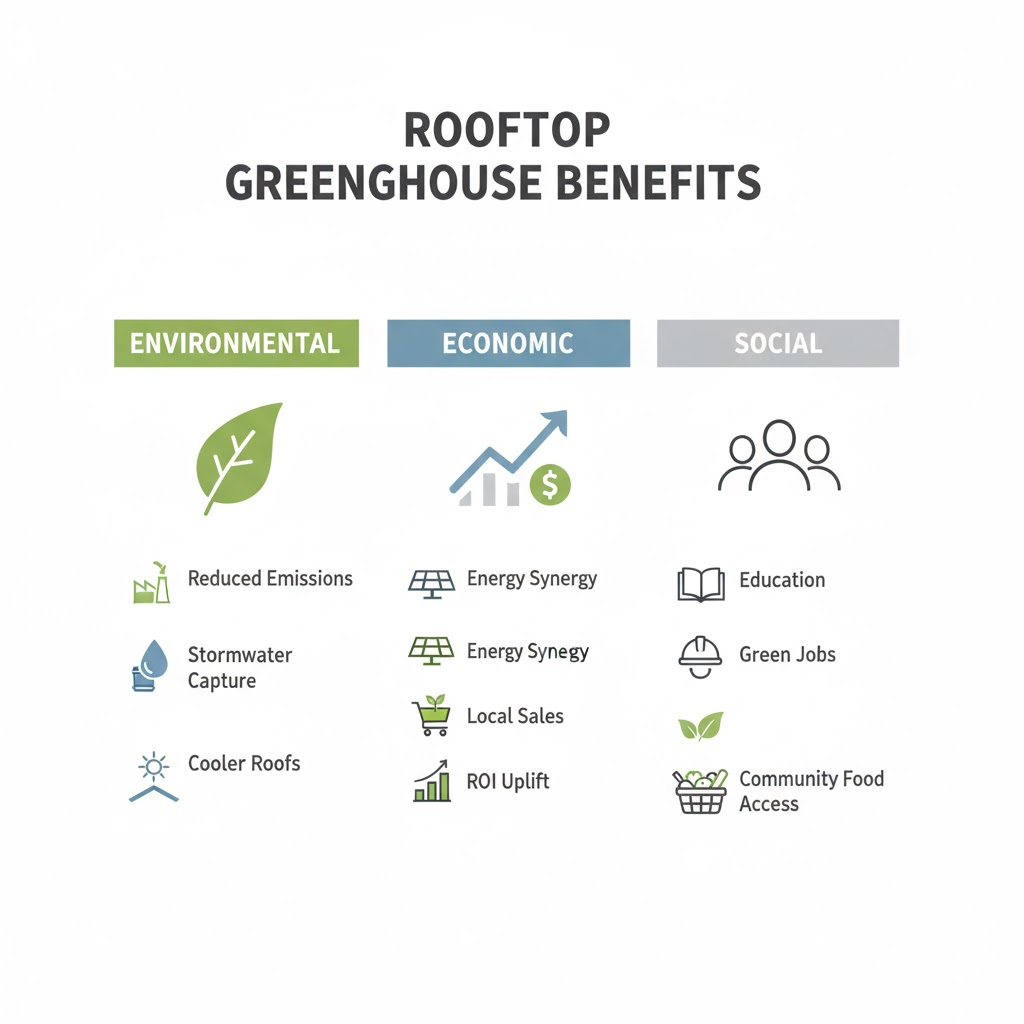

Environmental—Reduced Food Miles, Lower Emissions, Stormwater Management, Urban Heat Island Mitigation, Air Quality

Producing food where people live cuts transport distances (“food miles”) and associated emissions; a 2022 global analysis estimated transport contributes nearly 20% of food-system greenhouse-gas emissions. Rooftop greenhouses can further lower a building’s heating/cooling demand, capture and reuse rainwater, and help mitigate urban heat islands, especially when paired with vegetated roof assemblies and high-albedo surroundings. Green infrastructure guidance also notes co-benefits such as particulate capture and runoff control.

Practical example: A 1,000 m² rooftop in a rainy climate can often harvest enough water to cover a large share of leafy-green irrigation for the year, while reducing combined sewer overflows.

Economic—Energy Synergy, Operating Cost Savings, ROI/Property Value

By sharing heat, air, and sometimes ventilation with the host building, rooftop greenhouses can shrink heating loads in winter and reduce solar heat gain through the roof in summer. Studies of building-integrated greenhouses show meaningful energy co-benefits when ventilation and heat exchange are designed together. These efficiencies, coupled with local sales and premium freshness, improve operating margins; added urban green amenities can also enhance property value.

Practical example: Pairing exhaust-air heat recovery with a thermal screen can shave winter gas consumption while maintaining night temperatures for fruiting crops.

Social—Local Food Access, Education, Community Engagement

Rooftop greenhouses bring fresh produce into neighborhoods, support food education, and create visible, optimistic spaces above the street. Reviews of rooftop agriculture highlight community and educational missions as a core driver, with many sites hosting tours, school programs, and job training.

Practical example: Weekly tours and workshops create paid programming for operators while building community support for urban agriculture.

Types & Use Cases

Commercial Rooftop Greenhouses

Urban producers operate hydroponic or substrate systems at commercial scale, selling to retailers, restaurants, and direct-to-consumer channels—prioritizing crops that travel poorly and benefit from freshness. Global surveys show commercial rooftop greenhouses growing but still a subset of total rooftop agriculture.

Residential Rooftop Greenhouses

Homeowners or small multifamily buildings install compact structures for household produce, herbs, and season extension, selecting low-mass systems and lighter coverings that match the building’s load capacity. Guidance emphasizes structural and waterproofing diligence for these smaller installs.

Community/Educational Rooftop Greenhouses

Schools and community groups use rooftop greenhouses for hands-on learning and year-round programming; New York’s Sun Works Center is a well-documented example of a rooftop greenhouse classroom with hydroponics and data-logging.

New-Build vs. Retrofit Installations

New buildings can size structure, vertical access, and utilities for a greenhouse from day one; retrofits require careful verification of roof load paths, wind uplift, and access for materials (hoists, cranes, or large elevators). Technical literature catalogs these planning and operational differences for commercial RTGs.

Year-Round vs. Seasonal Operations

Year-round CEA models add heating, dehumidification, and supplemental lighting; seasonal installs lean on passive ventilation and shading to manage summer peaks. Reviews describe both approaches, with year-round models favored where proximity and reliability justify energy inputs.

Design & Structural Requirements

Structural Load, Wind Uplift, and Seismic Considerations

Roofs must be checked for dead/live loads from framing, glazing, water, crops, equipment, and snow; lateral systems must address wind uplift and, in seismic zones, bracing and connections that accommodate drift. Engineering bodies highlight load increases from rooftop assemblies and the need for secure tie-downs/curbs for rooftop structures.

Roof Compatibility, Access/Egress, and Safety

Feasibility hinges on safe access, egress, and logistics (stairs/elevators sized for materials; crane access if needed), plus code-compliant fall protection and perimeter safety during construction and operations. Vendor and design guidance stress planning these constraints early.

Waterproofing, Drainage, and Thermal/Vapor Barriers

A continuous roof membrane, proper curb details, leak testing, and robust drainage (scuppers/overflows) protect the building. Where the greenhouse shares air with the building, designers also manage vapor and thermal breaks to avoid condensation. Stormwater best-practice manuals provide applicable detailing principles.

Glazing and Covering Materials

Common options include horticultural glass, double glazing, rigid plastics (polycarbonate, PMMA), and advanced films. Selection balances PAR transmission, U-value, weight, impact resistance, lifespan, and cost—criteria summarized in greenhouse technology reviews.

Roof Forms and Orientation

Venlo-type, gable, and curved (Quonset/Gothic) roofs dominate. Orientation and roof geometry influence light uniformity and energy; in PV-shaded houses, checkerboard or distributed patterns can even light distribution versus linear rows.

Shading Strategies and Light Management

Designs combine external shades, diffusing films, dynamic louvers, or photovoltaic (PV/OPV) elements. Literature shows that moderate, well-distributed PV shading can stabilize microclimate with limited yield impact; sun-tracking or patterned arrays improve uniformity.

Shading options at a glance (guide)

- External shade cloths — Coverage: 20–60% | PAR impact: variable | Use when: heat/light peaks | Notes: low cost, flexible

- Diffusing films — Coverage: full skin | PAR: more uniform light | Use when: hot/sunny sites | Notes: reduces hotspots

- Fixed PV rows — Coverage: 10–40% | PAR: localized shade | Use when: power + shade needed | Notes: checkerboard improves uniformity

- Semi-transparent OPV — Coverage: 20–50% | PAR: passes plant-useful light | Use when: net-energy goals | Notes: spectral tuning potential

- Dynamic louvers/blinds — Coverage: variable | PAR: on-demand | Use when: rapid weather swings | Notes: higher CapEx/controls

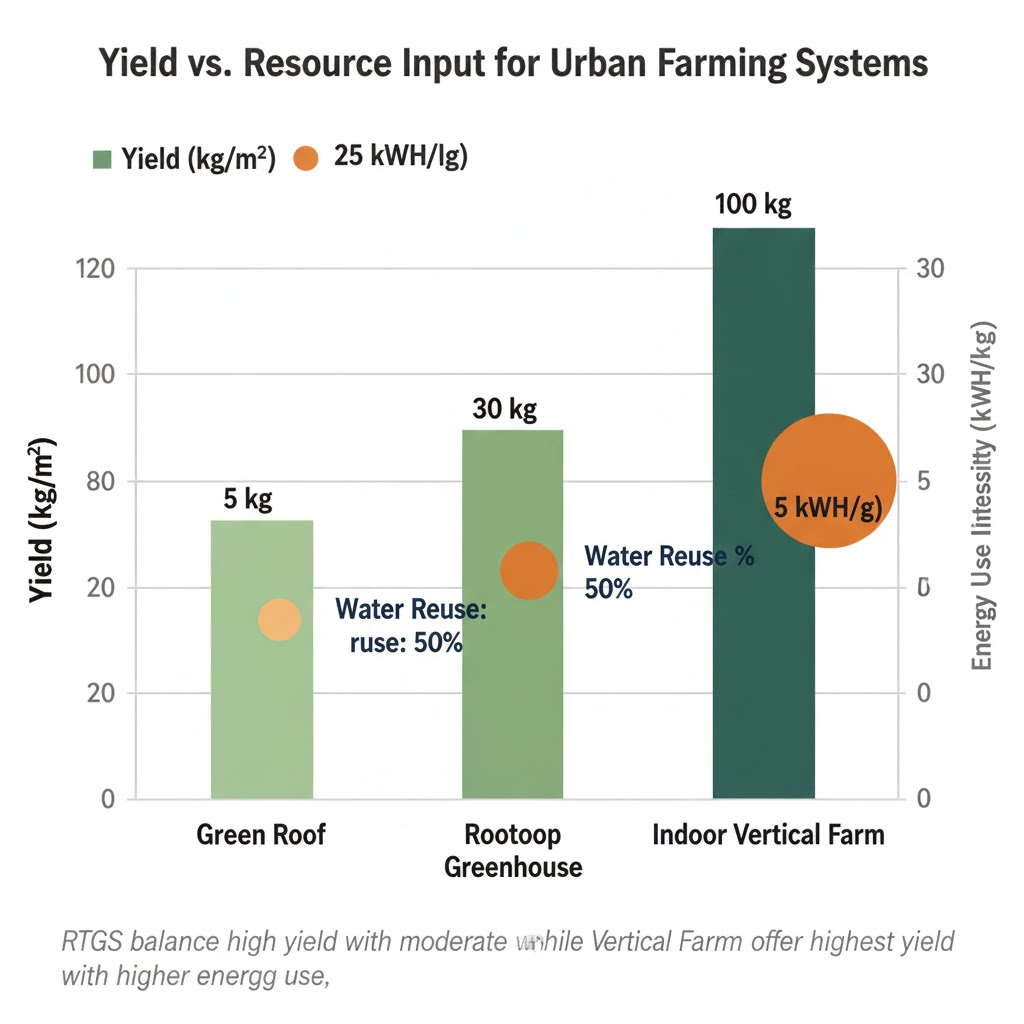

Comparison (summary): RTG vs Green Roof vs Indoor Vertical Farm

- Rooftop Greenhouse (RTG): Enclosed, high control; moderate–high CapEx; medium energy; high yields with sunlight + LEDs.

- Green Roof: Open, low control; low CapEx; minimal energy; ecosystem benefits, limited edible output.

- Indoor Vertical Farm: Fully enclosed; highest CapEx; highest energy (lighting/HVAC); very high density yields, no weather risk.

Growing Systems & Climate Control

Hydroponics, Aquaponics, Soilless/Substrate, and Soil

Hydroponics (NFT, DWC, drip) dominates commercial RTGs for water/yield efficiency; aquaponics integrates fish waste as nutrients; substrate (coco/rockwool) or soil systems suit small/community sites. Recent reviews outline equipment, management, and scale trade-offs for each.

Ventilation, Heating/Cooling, Humidity and CO₂ Control, Automation

Urban rooftop climates swing fast; balanced ventilation, dehumidification, and heating/cooling maintain target VPD and temperature, while CO₂ supplementation sustains photosynthesis during tight envelope operation. CEA automation and sensing reduce labor and stabilize outputs.

Supplemental Lighting (LED) and Controls

High-efficiency LEDs tailored to crop stage keep yields steady in winter or under heavy shading; work in i-RTGs shows yield and fruit-quality gains when LEDs complement limited natural light.

Irrigation, Fertigation, and Water Reuse

Closed-loop irrigation captures drain water; rooftop systems can also harvest rain and, where permitted, treat greywater for irrigation—tightening the Food-Energy-Water loop on site.

Energy & Water Integration

Waste-Heat Recovery and Building Energy Exchange

Coupling the greenhouse with building exhaust or heat recovery reduces winter heating; return air strategies and double-glazing/thermal screens trim losses. Measured and modeled studies report co-benefits when building and greenhouse systems are co-designed.

Solar PV/OPV as Roofing/Shading

Semitransparent PVs—especially organic photovoltaics (OPV)—can generate power while passing plant-useful light. Modeling and field trials suggest OPV can help reach net-zero energy greenhouses in suitable climates and, at moderate coverage, maintain crop performance.

Rainwater Harvesting and Greywater Use

Roof area and greenhouse gutters enable sizable rain capture; studies show rooftop agriculture can offset irrigation demand with harvested rain, and i-RTGs may incorporate treated greywater within local regulations.

Food–Energy–Water (FEW) Nexus and Circular Systems

i-RTGs exemplify the FEW nexus by closing loops: capturing rain, reusing water, using waste heat/CO₂, and producing food where demand exists—lowering citywide resource intensity.

(Suggested visual here: “i-RTG flow diagram” with arrows for heat, water, CO₂ exchanges; add descriptive alt text.)

Crop Planning & Production

Crop Selection and Seasonality

Leafy greens, herbs, tomatoes, cucumbers, peppers, and specialty greens thrive in RTGs; local studies propose crop rotations that balance yield, diversity, and environmental performance across the year in Mediterranean-type i-RTGs.

Yield Expectations and Quality

Urban proximity favors tender, perishable crops where freshness commands a premium. Life-cycle and network analyses on rooftop tomatoes highlight energy hotspots and opportunities to optimize inputs without compromising quality.

IPM, Biosecurity, and Food Safety

Biological controls, screening, sanitation, and strict entry protocols maintain crop health in closed urban settings; greenhouse-specific IPM references outline pest monitoring and non-synthetic controls suited to year-round facilities.

Economics & Business Models

CapEx, OpEx, and Lifecycle ROI

Costs reflect structure, glazing, MEP integration, logistics, and automation; literature cites high up-front investments for year-round CEA, offset over time by energy integration and premium sales. Scenario analyses and case work emphasize careful lifecycle modeling.

Revenue Channels (CSA, Retail/B2B, On-Site Sales)

Operators blend subscription boxes, retail contracts, food-service, and on-site sales to diversify risk and match crop planning to demand patterns documented in urban greenhouse case studies.

Grants, Incentives, and Green-Building Credits

Depending on jurisdiction, projects may qualify for urban-agriculture, energy, or stormwater incentives; green-infrastructure programs often recognize runoff reduction and heat-island mitigation benefits.

Permits, Codes & Policy

Zoning and Land-Use Pathways

Cities increasingly update zoning to allow rooftop agriculture and greenhouses on commercial/industrial roofs; practitioners should verify allowable height/area exceptions and ancillary use definitions in local codes or “green” amendments.

Building Codes and Engineering Approvals

Projects require stamped structural analysis, fire/life-safety review, egress compliance, and wind/seismic checks. Technical guidance on rooftop assemblies underscores the importance of code-compliant connections, curbs, and load path verification.

Environmental and Health Regulations

Water reuse, nutrient management, and pesticide use must meet environmental and public-health rules; stormwater and backflow protections follow city utility guidelines common to green-infrastructure projects.

Case Studies & Examples

Lufa Farms (Montreal)

Lufa built the first commercial rooftop greenhouse (2011) and expanded in 2020 with what was then billed as the world’s largest rooftop greenhouse—supplying tens of thousands of weekly produce baskets in the Montreal region.

Outcomes (illustrative): Year-round greens and tomatoes with short delivery radii; subscription model strengthens recurring revenue.

Gotham Greens (United States)

Gotham Greens’ 20,000-sq-ft greenhouse on Whole Foods Market’s Brooklyn rooftop (2013) became the first supermarket-integrated rooftop greenhouse in the U.S., supplying the store and nearby restaurants year-round.

Outcomes (illustrative): In-store freshness advantage; reduced refrigerated transport; strong brand synergy with host retailer.

Educational/Community Examples (e.g., Sun Works Center)

The Sun Works Center rooftop greenhouse classroom integrates hydroponics, aquaponics, and monitoring for K–12 science learning—an early template for education-first RTGs.

Outcomes (illustrative): STEM curriculum integration; student-run lettuce/herb production for cafeterias.

Challenges & Risk Management

Engineering Constraints and Limited Space

Structural reserve, crane access, and rooftop MEP capacity can cap project size; rigorous pre-design surveys limit surprises during permitting and build.

Upfront Costs and Financing Options

Capital intensity is the chief hurdle; projects frequently blend private capital with grants or green-infrastructure incentives to close gaps identified in RTG economics literature.

Operational Complexity and Staffing

Year-round CEA demands skilled operations, 24/7 monitoring, and playbooks for climate anomalies; sector reviews stress automation and training to maintain consistency.

Resilience to Climate Extremes and Supply Risks

Heat waves, cold snaps, and supply chain shocks (substrates, nutrients) require redundancy in shading, backup power, and supplier networks, plus building-level coordination to stay online during grid stress.

Troubleshooting & Quick Fixes (new)

- Condensation/drips: Add thermal breaks and double glazing; increase night airflow; deploy anti-drip films.

- Roof leaks: Inspect curb flashing; re-seal penetrations; test with controlled water spray before re-opening.

- Hot spots/light burn: Use diffusing films or deploy shade screens during midday peaks; adjust LED distance/PPFD.

- Pest ingress: Seal screens/doors; add anteroom; tighten sanitation schedules; start biocontrols early.

- Nutrient imbalance: Calibrate EC/PH; flush lines; validate stock solution concentrations.

- Controller misreads: Re-calibrate sensors; check placement away from drafts or direct sun; verify firmware.

Future Trends & Innovations

AI-Driven CEA, Sensors, and Digital Twins

Edge sensors, computer vision, and predictive controls are moving from pilot to practice in CEA—helping operators fine-tune climate and irrigation at plant level while reducing labor.

Advanced Materials (OPV, Smart Glazing)

Spectrally selective OPV and electrochromic/diffusing glazings promise better light partitioning between plants and power, with models and trials pointing toward net-zero RTGs in favorable climates.

Retractable/Open-Roof Systems

Retractable structures and dynamic shading let growers rapidly shed heat or admit rainfall where appropriate, blending greenhouse control with open-air benefits; PV checkerboard and movable blinds further refine light distribution.

Emerging Policy Frameworks

Cities continue to formalize rooftop agriculture in planning, stormwater, and green-building programs, improving certainty for developers and owners as evidence of co-benefits accumulates.

Advanced Design Options (for power users)

- CFD + energy modeling to size vents, fans, and screens.

- Spectral tuning for OPV to pass PAR while harvesting NIR.

- Dynamic setpoints (temp/CO₂/VPD) by crop stage and forecast.

- Sun-tracking PV blinds to balance electricity and PAR.

- Data pipelines for yield forecasting + SKU planning.

Quick-Start Checklist

Feasibility and Structural Assessment

Commission a structural survey (dead/live loads, wind/seismic), membrane condition check, and drainage study before concept design.

Team and Partner Selection

Assemble an integrated team: structural and MEP engineers, envelope specialist, greenhouse/CEA designer, code consultant, and O&M lead with urban CEA experience.

Concept Design, Budgeting, and Permitting

Lock program (crops, throughput), size utilities, choose glazing and climate systems, and map permitting/zoning path alongside a lifecycle energy and water model.

Pilot, Build, Commissioning, and O&M Plan

Pilot crops and SOPs at small scale; commission climate, irrigation, and controls; implement monitoring and IPM plans before ramping to full production.

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.