Solar Panel Cleaning Equipment

Written by Admin | Nov 20, 2025

What Counts as Solar Panel Cleaning Equipment?

Direct answer: Solar panel cleaning equipment includes safe tools and systems that remove soiling from PV glass without damaging modules or voiding warranties.

Solar panel cleaning equipment includes any tool or system designed to safely remove dust, grime, salts, bird droppings, pollen, ash, or industrial fallout from PV glass without harming modules, frames, wiring, or warranties. It spans hand brushes and water-fed poles, pure-water (RO/DI) systems, low-pressure pumps, rotating brush heads, robots (wet and waterless), drone sprayers, and accessories that make work faster and safer. Robust maintenance guidance comes from international standards that explicitly include cleaning within PV O&M.

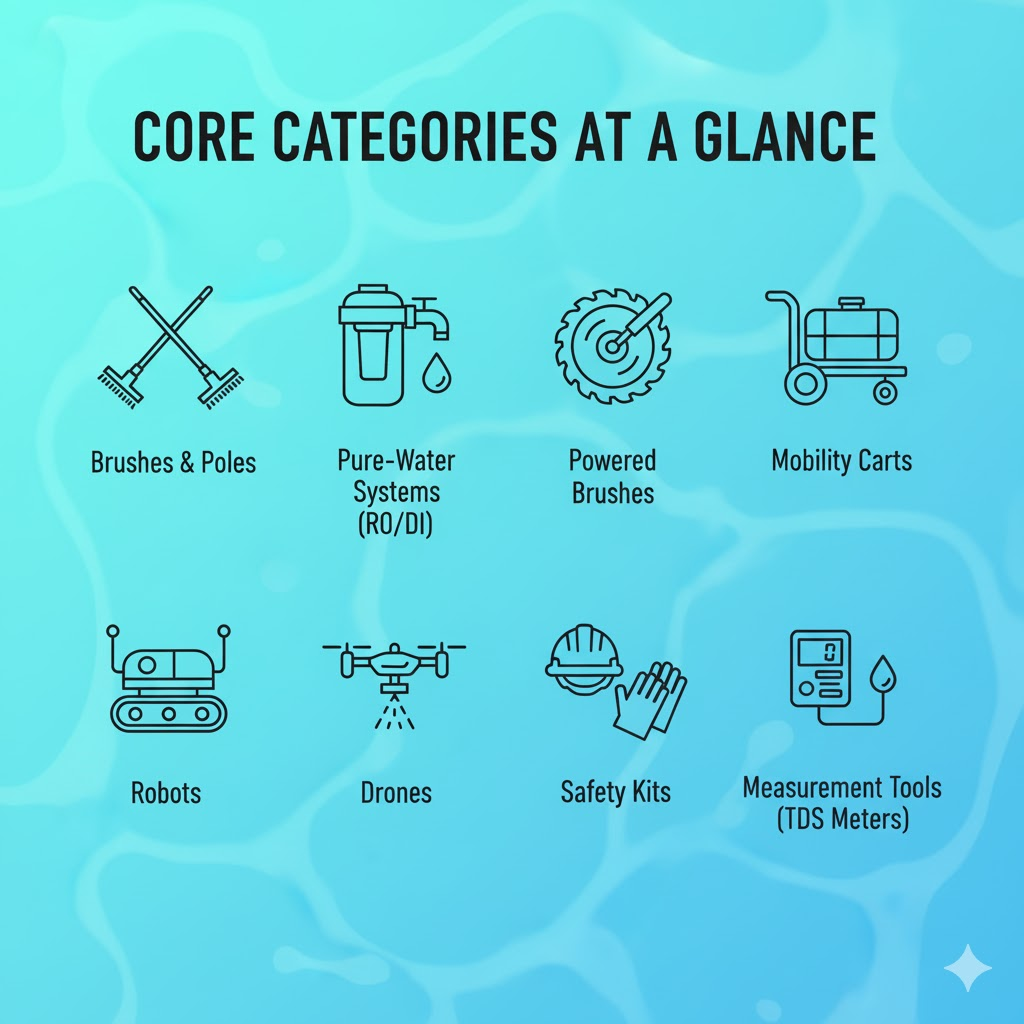

Core Categories at a Glance

- Manual contact tools: non-abrasive brushes, pads, squeegees, microfiber.

- Water delivery: RO/DI carts, tanks, hose reels, valves, flow controls.

- Powered brushes: rotating/oscillating heads sized for panel width.

- Mobility platforms: poles, lightweight carts, van/trailer builds.

- Measurement & QA: TDS meters, flow gauges, soiling sensors.

- Automation: autonomous robots (waterless or wet), semi-auto crawlers.

- Aerial solutions: drone sprayers for hard-to-reach sites.

- Safety kit: fall-protection, anchors, lifelines, helmets, gloves.

Equipment Categories

Brushes & Poles (Manual)

Manual gear is the backbone for homes and small commercial arrays. Look for soft, flagged bristles, edge guards, and pad options for stubborn spots. A well-balanced pole reduces fatigue and helps you keep steady, gentle pressure—important for coated glass.

Benefit example: Ideal for tight residential roofs where lifts aren’t practical; lowest cost, lowest learning curve.

Suggested visual: Photo of a soft-bristle brush with edge guard on a panel corner.

Telescopic Water-Fed Poles (RO/DI-Compatible)

Water-fed poles move purified water through the brush so you can rinse as you scrub. Using deionized or reverse-osmosis water avoids mineral spots that steal shine. Clean when modules are cool to reduce thermal stress on glass and laminates. For detailed temperature and pressure limits, see Safety & Risk Management → Electrical & Thermal Hazards and Pressure-Washer Risks & Safe Alternatives.

Benefit example: Faster than manual bucket-rinse methods; no ladder needed for typical single-story arrays.

Suggested visual: RO/DI-fed pole rinsing glass; caption: “Purified water prevents spotting.”

Rotating / Oscillating Brushes (Width, Bristle, Angle)

Powered heads raise productivity on long rows. Match brush width (e.g., ~600–1000 mm) to module spans and pick softer bristles for delicate AR coatings; angle adapters help keep full bristle contact as you work along tilt. (Manufacturers commonly pair these with 24 V motors and multi-jet manifolds.)

Benefit example: Cuts passes per row and reduces shoulder strain on carports or long commercial strings.

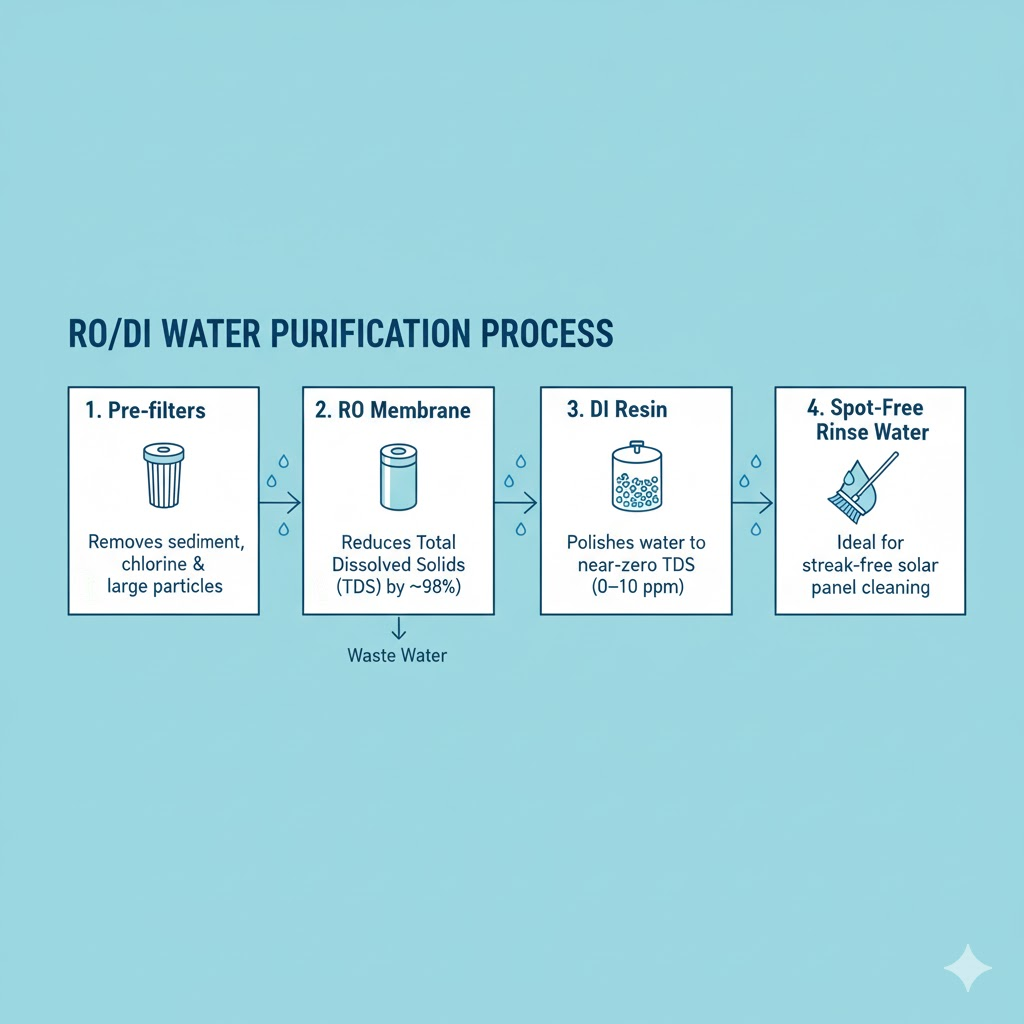

Pure-Water Systems (RO/DI)

RO/DI carts strip minerals that cause spotting. Inline TDS meters help you know when resin or membranes need attention; zero-to-low TDS output delivers that “spot-free” finish pros expect.

How RO/DI works (quick steps):

- Pre-filters remove sediment/chlorine.

- RO membrane drops TDS dramatically.

- DI resin polishes to ~0–5 ppm for spot-free dry-down. Suggested visual: Simple RO/DI flow diagram with “TDS meter” callout.

Portable Carts, Vans & Trailers

Mobile setups bundle tanks, filtration, pumps, reels, and storage so crews can service multiple roofs efficiently without tapping site water.

Benefit example: Higher first-cost, but big time savings across multi-stop days.

TDS Meters, Filters & Resin Management

Resin can exhaust quickly in hard-water regions. Track TDS and change resin or pre-filters before spotting creeps back in—your finished glass tells the tale.

Troubleshoot: If TDS won’t drop after DI, resin is likely exhausted; swap resin or check RO output.

Cleaning Agents (pH-Neutral, Biodegradable)

Chemicals are niche tools for sticky residues. Favor pH-neutral, biodegradable formulas and rinse thoroughly. Many module makers allow mild detergents but emphasize cool panels, soft materials, and avoiding abrasives.

Benefit example: Helps with sap, bird residue, or cement dust—but keep it gentle and rare.

When to Use Chemicals vs Pure Water

Start with RO/DI water; escalate only if contaminants resist. Several manufacturers recommend low-pressure water matched to module temperature—or dry brushing in arid sites—before considering soaps. For product selection guidance, see Cleaning Agents (pH-Neutral, Biodegradable) above.

Pumps & Low-Pressure Rinsing (Pressure-Washer Cautions)

Use pumps for steady, gentle flow—not force. High pressure risks seals and glass; one maker caps cleaning water pressure < 690 kPa and limits water–glass temperature differences to a narrow band. For exact safety margins and examples, see Safety & Risk Management → Pressure-Washer Risks & Safe Alternatives.

Robotic Cleaners (Waterless & Wet)

Robots shine on utility-scale rows where manual access is slow. Waterless systems use microfiber + airflow for nightly dust control in deserts; wet systems combine brushes and limited water for heavy grime. Look for proven pressure control and safe panel contact. (For water savings and runoff planning, see Environmental & Regulatory Considerations → Water Use, Reclamation & Runoff.)

How waterless robots work:

- Soft pads or microfiber lift dry dust at night when glass is cool.

- Gentle airflow moves loosened particles off modules.

- Frequent passes keep accumulation low between deeper cleans. Suggested visual: Robot spanning two modules at night.

Drone-Based Cleaning Systems

Aerial sprayers help where lifts are unsafe or roofs are hard to reach, bringing targeted rinses from altitude. They’re emerging quickly in 2024–2025 with pro trials and commercial systems in service. (Match pressure and water temperature to module guidance.)

Benefit example: Reduces ladder work on awkward roofs; good for spot cleanups.

Accessories & Add-Ons

These small choices shape your day: angle adapters maximize bristle contact; inline valves save steps; microfiber and squeegees detail edges; and safety gear keeps you focused when the wind kicks up.

Suggested visual: Flat-lay of adapters, valves, and nozzles with labels.

How to Choose the Right Setup

Direct answer (AEO-ready): Choose gear by access, climate/soiling, water quality, warranty limits, and economics—then size tools to your crew and array.

Array Type & Access (Roof, Ground, Utility-Scale)

Rooftops reward light poles and compact carts; ground mounts benefit from wider brushes; utility-scale sites are prime for robots or tractor-mounted arms to cover kilometers of rows without stepping on frames.

Soiling Profile & Climate (Dust, Pollen, Bird Droppings)

Dust, salts, and agricultural particulates drive different plans. Soiling is the next-largest driver of energy loss after irradiance in many climates, with arid sites hit hardest—so cleaning strategy must follow local conditions.

Water Availability & Quality (TDS Targets)

Where water is scarce, waterless robots or dry brushing can protect output while conserving resources; where water is hard, RO/DI avoids residue. Clean when modules are cool to prevent thermal shock.

Panel Coatings & Warranty Requirements

Follow your module manual for what’s permitted (materials, pressure, temperature). Improper cleaning can void coverage—check the brand’s cleaning annex before you roll.

Productivity & Crew Size (Coverage per Hour)

Match tool width and power to your crew. Rotating heads and RO/DI carts boost hourly coverage; robots remove walking time on vast arrays.

Power Source, Portability & Storage

Battery packs, backpack tanks, and hose-reel layout influence fatigue and job time. Plan for safe transport and winterizing filters and pumps.

Compliance & Standards (IEC 62446-2, OSHA)

IEC 62446-2 frames PV maintenance practices (including cleaning). Pair that with OSHA fall-protection rules for rooftop work and you’ll align safety with performance.

Equipment Configurations by Use Case

Residential Service Kit (One- or Two-Person Crew)

A practical kit: 20–30 ft water-fed pole, soft brush, RO/DI cart with TDS meter, lightweight hose + reel, and PPE. Good reach and spot-free rinsing without ladders.

Commercial Rooftop Package (Multi-Story Access)

Longer poles, larger RO/DI capacity, quick-connect manifolds, angle adapters, and roof anchors. Plan routes to minimize hose runs and trip hazards.

Utility-Scale Solutions (Autonomous & Fleet Options)

For deserts and large ground mounts, consider waterless robots for nightly passes or wet robots for periodic deep cleans, integrated with site SCADA for scheduling.

Key Specs & Sizing Guidelines

Pole Length vs Working Height

Choose poles that reach comfortably above the top row from safe footing; stiffer sections make long days easier on shoulders.

Brush Width, Bristle Type & RPM

Match brush width to module geometry; softer bristles protect AR coatings; moderate RPM with adequate flow lifts dirt without scouring.

Flow Rate & Pump Sizing

Aim for steady, low-pressure flow that keeps the glass flushed as you brush; oversizing only increases splash and water use.

TDS for Spot-Free Rinse

Use RO/DI output and watch the meter; when TDS creeps up, swap resin/media to avoid haze or spotting on dry-down. (Hard water leaves residue; purified water avoids it.)

Comparison (add-on table for user value)

| Method | Best For | Coverage / hr (relative) | Water Use | Upfront Cost | Notes |

| Manual brush + RO/DI pole | Homes, small rooftops | Medium | Low–Medium | Low | Simple, low risk |

| Rotating brush head | Long rows, carports | High | Medium | Medium | Faster passes |

| Waterless robot | Desert, scarce water | Very High (nightly) | Very Low | High | Great for dust control |

| Wet robot | Utility-scale grime | Very High | Medium | High | Deep clean with water |

| Drone sprayer | Hard-to-reach roofs | Medium | Medium | Medium–High | Targeted rinses |

RO vs DI vs RO/DI (quick view)

| System | Typical TDS Output | Consumables | Pros | Cons | Best Use |

| RO only | ~5–20 ppm | Membrane, pre-filters | Big TDS drop | Slower flow | Very hard water |

| DI only | ~0–5 ppm | Resin | Spot-free finish | Resin cost | Moderate water, small jobs |

| RO/DI combo | ~0–5 ppm | Membrane + resin | Fast + spotless | Highest kit cost | Pro crews, variable water |

Maintenance & Care of Your Gear

Brush Wear & Replacement

Replace heads when bristles mushroom or feel scratchy; edge trim that frays can leave tracks.

Filter & Resin Change Intervals

Follow pressure drops and TDS readings rather than calendar time—source water varies widely.

Pump, Hose & Fittings Upkeep

Flush after chemical use, inspect O-rings, and drain for freeze protection to extend service life.

Robot Batteries, Software & Spare Parts

Keep packs balanced, update firmware, and stock belts/brushes so long rows don’t wait on shipping.

Troubleshooting Tips (quick fixes)

- RO/DI TDS won’t drop: Replace DI resin; check RO membrane and pre-filters.

- Brush leaves tracks: Bristles are worn or contaminated—swap head, rinse brush.

- Robot slipping: Inspect pads, adjust tilt/pressure; avoid runs on hot glass.

- Spotting after dry-down: TDS crept up—polish with DI, slow the final rinse.

- Weak pump flow: Check battery charge, inlet strainers, and hose kinks.

Safety & Risk Management

Fall Protection & Access Systems

Use anchors, lifelines, and guardrails per job design; assign a competent person to inspect gear and conditions before work begins.

Electrical & Thermal Hazards (Cool-Panel Windows)

Work when panels are cool—early or late. Sudden temperature shocks from cold water on hot glass can crack modules.

Lockout/Tagout for O&M Teams

Coordinate with site ops so automated trackers or inverters don’t surprise crews mid-clean.

Pressure-Washer Risks & Safe Alternatives

Avoid high-pressure lances near frames, seals, and junctions. If a pump is used, keep pressures low and water temperature close to glass temperature.

PPE Checklist

Helmet, harness, non-slip footwear, cut-resistant gloves, eye/respiratory protection when using chemicals or blowing dust.

Environmental & Regulatory Considerations

Water Use, Reclamation & Runoff

Plan containment on tight sites. Waterless robots reduce consumption where supply is scarce and help comply with drought policies.

Waterless Options for Drought Regions

Nightly dry cleaning can stabilize output between rare rains on desert sites while minimizing truck rolls.

Chemical Selection & Local Discharge Rules

Use biodegradable, pH-neutral agents sparingly and follow local discharge ordinances for gray water.

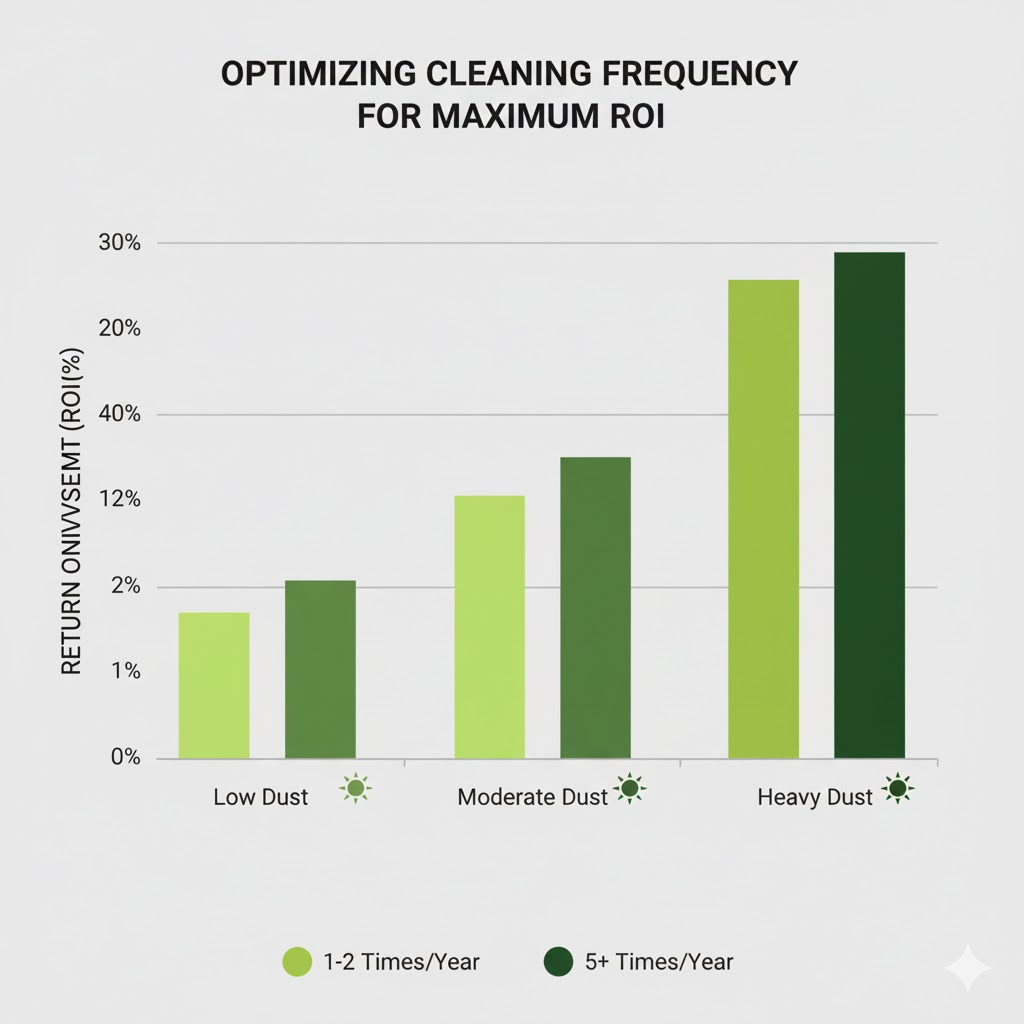

ROI & Cleaning Frequency

Direct answer (AEO-ready): Clean when measured soiling and economics say it’s profitable—use data, not the calendar.

Soiling Loss Benchmarks by Climate

Annual energy loss to soiling can vary widely by region; tools now quantify it via the Insolation-Weighted Soiling Ratio (IWSR)—for example, IWSR = 0.95 implies ~5% annual loss.

Mini case study (user value)

A 2 MW desert ground mount saw a 6–8% drop in PR after a windy month. A nightly waterless robot pass plus a monthly RO/DI deep clean restored output within 48 hours and reduced truck rolls by ~40% over the quarter.

When Manual, Robotic or Drone Cleaning Pays Off

Economics depend on soiling rate, rainfall, electricity price, and cleaning cost. Studies show optimization—not fixed schedules—maximizes value; in dusty zones, automated or nightly waterless passes often pencil out.

Scheduling Tools & Data Sources (e.g., NREL Soiling Maps)

Use regional soiling maps and modeling (NREL, Solargis) plus your site’s PR/SCADA data to trigger cleans at measured thresholds rather than on a calendar.

Advanced: Monitoring & Triggers

- Track IWSR/SR and set action thresholds (e.g., -3% weekly).

- Compare PR vs. modeled output; clean when variance exceeds target.

- Use weather + wind/dust alerts to pre-schedule passes.

- Log post-clean PR to validate ROI and refine thresholds.

Frequent Ask Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.