Vinyl vs. Fiberglass Windows

Written by Admin | June 22, 2025

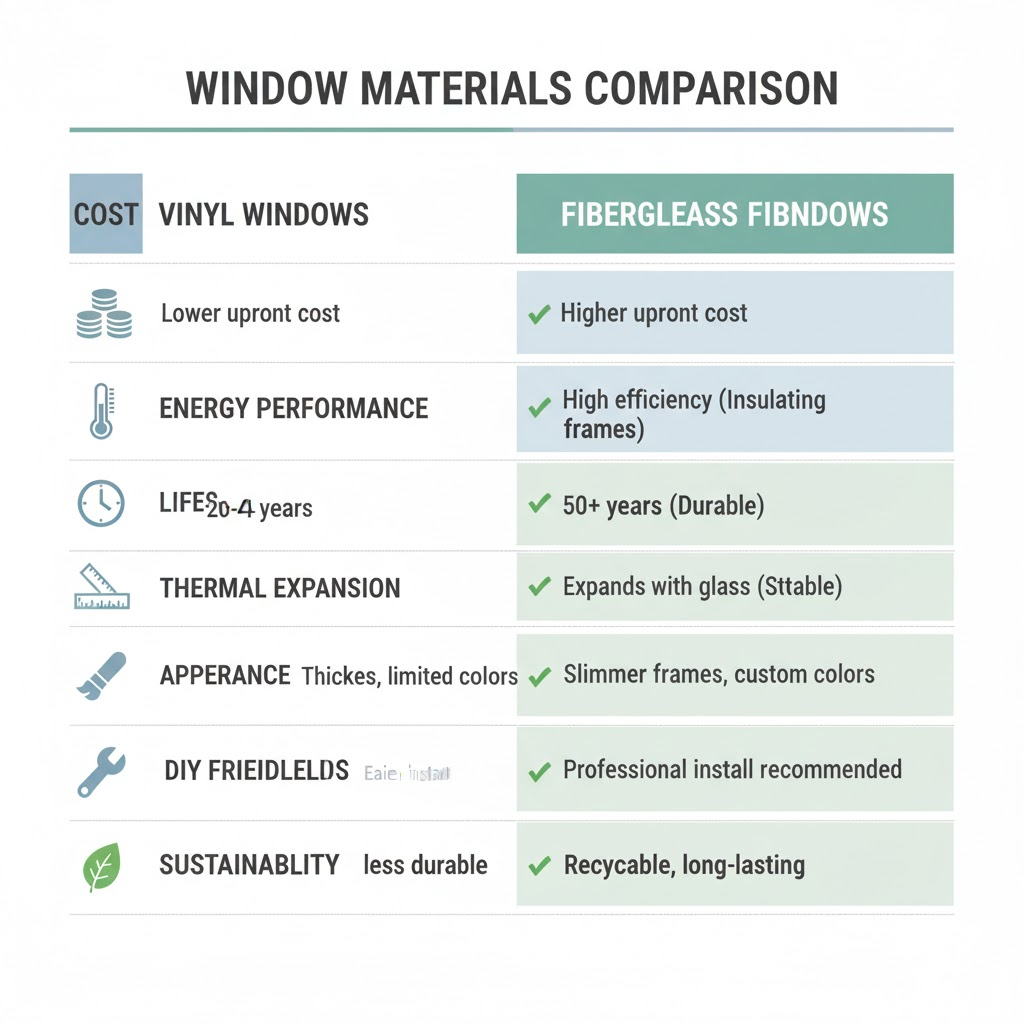

Key Differences at a Glance

What They’re Made Of & Why It Matters

Vinyl (PVC) Frames

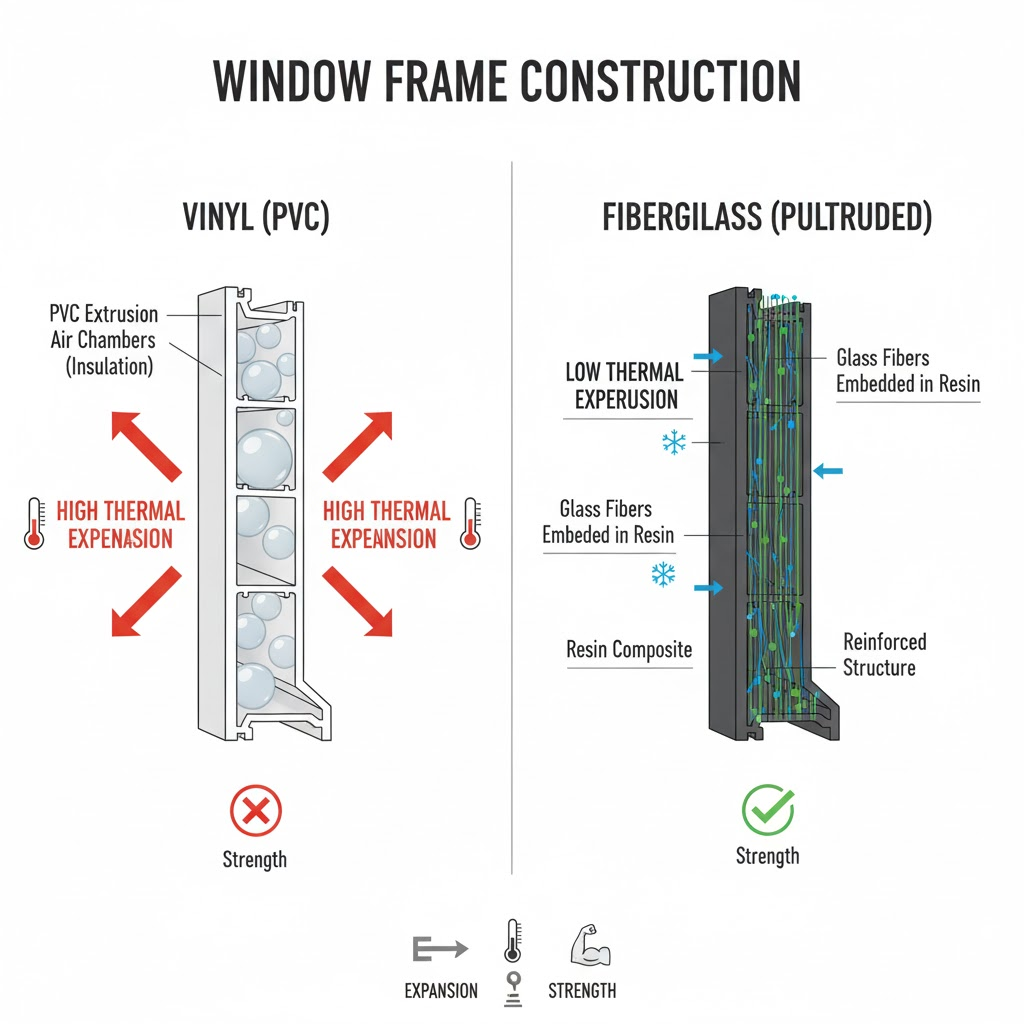

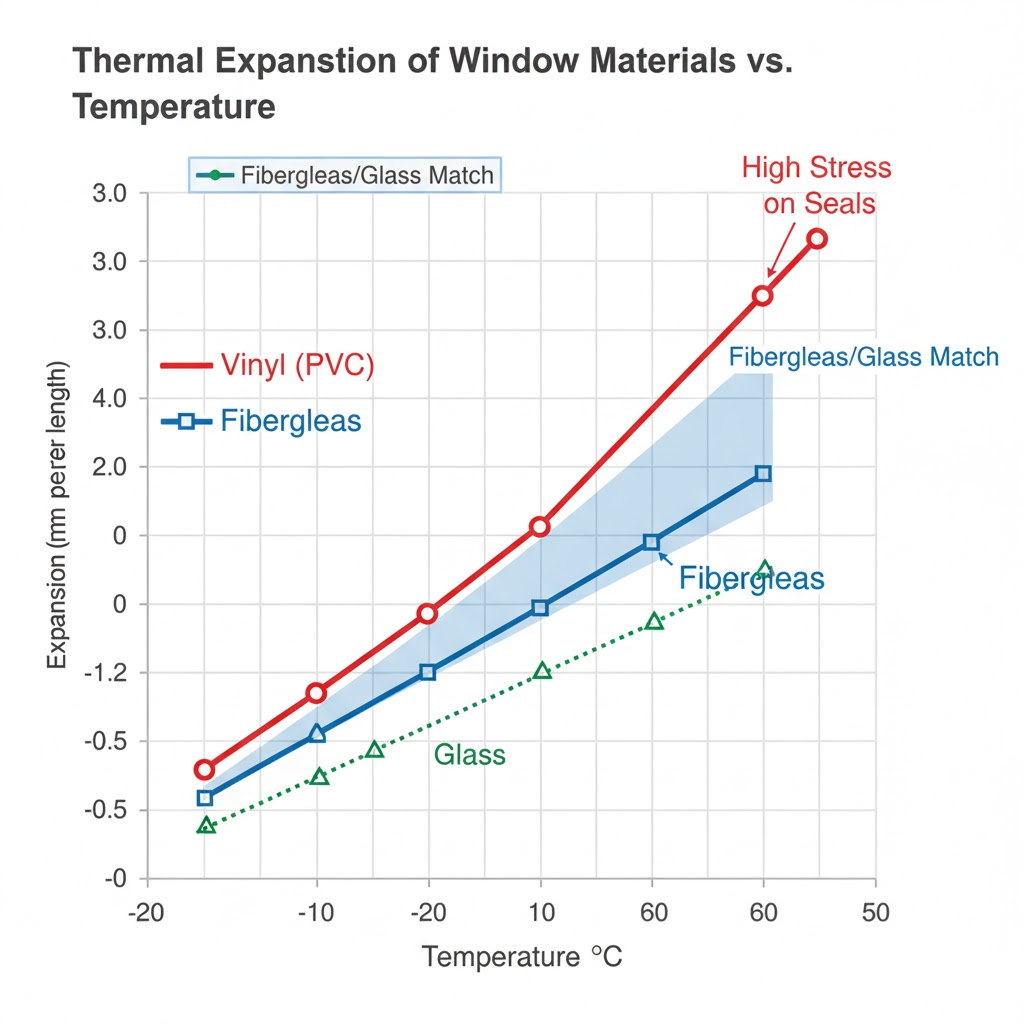

Vinyl frames are extruded from polyvinyl chloride (PVC). They insulate well and keep costs down, but PVC is a thermoplastic that expands and contracts more with temperature swings than glass does. That movement can influence long-term air- and water-tightness if tolerances or installation aren’t spot-on.

Fiberglass (Pultruded Glass-Fiber) Frames

Fiberglass frames are typically thermoset composites made by pultrusion: glass fibers are pulled through resin and cured into stiff profiles. This chemistry yields low thermal expansion—similar to the insulated glass unit—so seals and gaskets see less stress over decades. Many makers highlight high strength-to-weight and dimensional stability as key benefits.

Quick Glossary (scan-friendly)

- U-factor – Whole-window insulation (lower = better).

- SHGC – Solar heat admitted (choose lower in hot-sunny climates; sometimes higher for south-facing windows in cold zones).

- AL (Air Leakage) – Draft potential (lower = tighter).

- Low-E – Thin coating that reflects heat to reduce loss/gain.

- Warm-edge spacer – Reduces edge heat loss and condensation risk.

- DP/PG – Structural rating (Design Pressure/Performance Grade) for wind/water loads.

Cost & Value

Material & Installation Costs

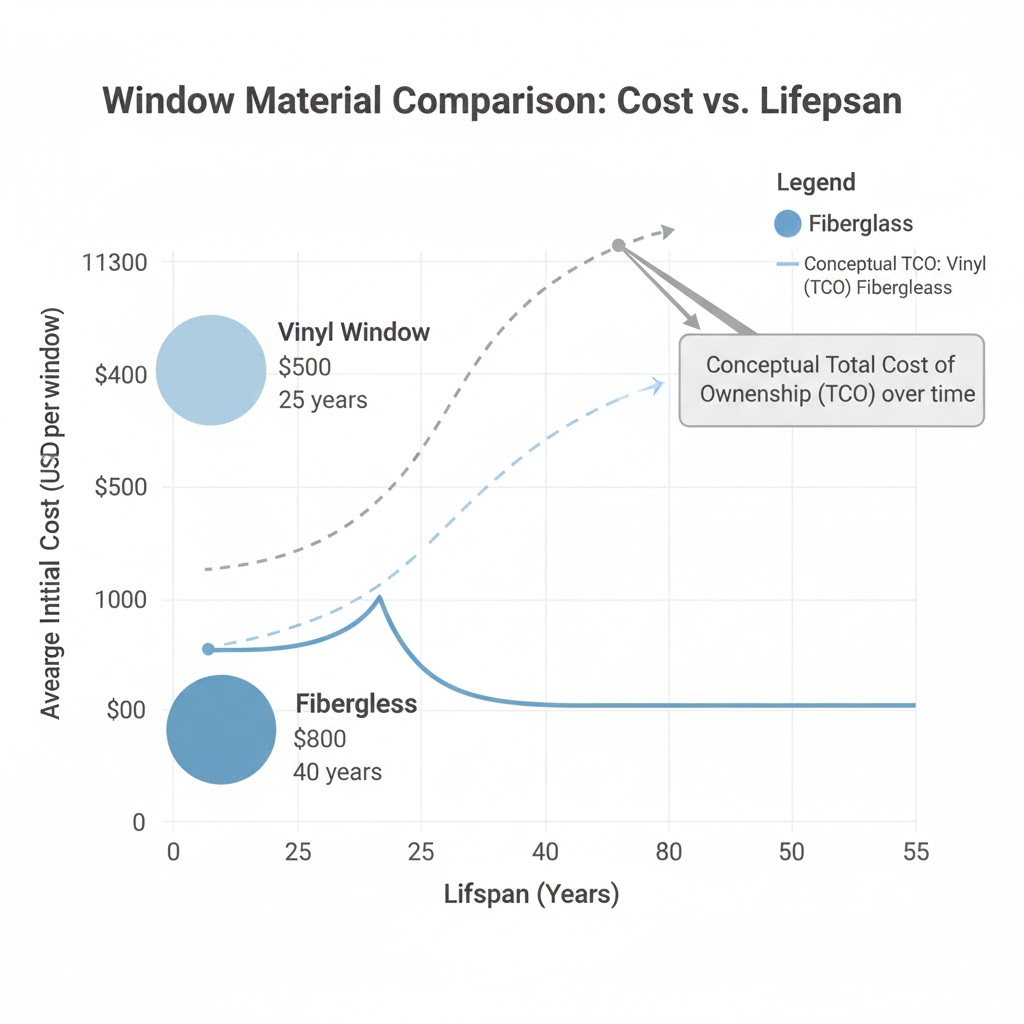

Vinyl windows generally cost less and are stocked in many sizes; fiberglass often carries a premium and is more likely custom-built. Total project price still hinges on glass packages, sizes, options, and labor. Industry roundups and buyer guides consistently show vinyl’s lower median cost and fiberglass in a higher band.

Lifespan, Warranty & Total Cost of Ownership

Service life varies by product and climate, but reputable references place vinyl around 20–30 years and fiberglass extending beyond that when maintained and properly installed. Lower expansion and rigidity can help fiberglass preserve glazing seals, delaying service issues that drive lifetime cost.

Resale Value Considerations

Resale impact is measured in whole-home ROI. Recent Cost-vs-Value analyses report vinyl window replacement commonly recoups about two-thirds of project cost at sale; wood is similar. Fiberglass isn’t always broken out separately, but premium performance and aesthetics can aid buyer appeal.

Owner story (illustrative): A 2003 Colorado home received quotes for 11 windows + 1 patio door—vinyl ≈ $14.5k vs fiberglass ≈ $28.5k. With a 5–10 year stay, the owner prioritized payback and chose vinyl.

Energy Performance & Climate Considerations

U-Factor, SHGC & Air Leakage Ratings (What to Look For)

Focus on the NFRC label:

U-factor (lower = better insulation) is a whole-window rating.

SHGC (lower = less solar heat admitted) should match your sun/exposure.

Air Leakage (lower is better; many top operable units target ≤0.3 cfm/ft²) influences drafts and comfort. ← tuned for accuracy

Cold, Mixed & Hot-Sunny Climates (Choosing the Right Specs)

Cold: prioritize very low U-factors; allow higher SHGC on sun-facing windows if winter solar gain is desirable.

Mixed: balance low U-factor with moderate SHGC based on orientation.

Hot-Sunny: pair low U-factor with low SHGC to limit heat gain. ENERGY STAR Version 7.0 tightened these targets in southern zones.

Orientation tip: South/west exposures in hot climates benefit from lower SHGC; in cold climates, some south-facing windows can intentionally use a higher SHGC for passive gain.

Operating type tip: Casements/awnings often seal tighter than sliders, which can help air leakage and comfort.

Glass matters most: Upgrading to better Low-E, gas fills, and warm-edge spacers typically moves the energy needle more than frame choice alone.

NFRC Label – How It Works (3 quick steps)

- Find U-factor, SHGC, and Air Leakage on the label.

- Compare against your climate target (cold/mixed/hot-sunny).

- Ensure the quote uses the same glass package when comparing vinyl vs fiberglass.

Durability & Structural Performance

Strength, Rigidity & Thermal Expansion

Fiberglass’ thermal expansion closely tracks glass, reducing stress on seals; PVC expands several times more over the same temperature change. That dimensional stability, plus high stiffness, is a core reason fiberglass frames are favored in demanding climates and large units.

Warping, Fading & UV/Heat Tolerance

Dark, heat-absorbing colors can challenge thermoplastics; many manufacturers caution against painting vinyl or using unapproved dark finishes because of heat distortion risk. Fiberglass tolerates dark paints better and can be factory-finished in deep tones. Always follow the specific brand’s finish and warranty rules.

Appearance & Design Flexibility

Frame Profiles & Sightlines

Fiberglass’ stiffness allows slimmer frames (more glass area) in many lines; vinyl frames can be bulkier to maintain strength. This affects daylight and the “clean” or “chunky” look you see from the curb.

Colors, Textures & Black Exteriors

Vinyl typically ships in limited integral colors; specialty dark-color technologies vary by brand and may come with conditions. Fiberglass is often offered in dark, contemporary palettes and can replicate wood grain convincingly. Check each maker’s dark-color guidance and warranty terms.

Paintability (Can You Paint Fiberglass?)

Yes—many fiberglass systems are paintable and supported by manufacturer guidance. Vinyl is generally not meant to be painted (heat/adhesion issues), and doing so can void warranties.

Maintenance & Upkeep

Both materials are low-maintenance: routine washing and track lubrication keep things moving smoothly. Painted fiberglass may need periodic repainting over long horizons; vinyl avoids painting but can benefit from periodic sealant checks in high-sun exposures.

Installation & Project Fit

Retrofit vs. New Construction

Insert (retrofit) projects often favor vinyl for availability and forgiving fit in sound frames. For full-frame replacements or new builds where opening geometry is critical, fiberglass’ rigidity and made-to-order approach can shine.

Insert Retrofit Checklist (quick)

• Frame must be sound and square • Sill pan or back dam • Flashing tape sequence • Low-expansion foam around frame • Backer rod + sealant • Interior trim touch-ups

Full-Frame/New Construction Checklist

• Proper WRB integration • Sloped sill pan • Corner/hinge-side reinforcement per size • Nailing fin fastening schedule • Flashing order aligned with ASTM E2112

Common Issues & Fixes (Troubleshooting)

• Drafts after install → check sash locks, perimeter foam, and exterior sealant continuity.

• Condensation at edges → confirm warm-edge spacer, interior humidity, and consistent air circulation.

• Sticking sashes → clean/lube tracks; verify plumb/level/shim points.

DIY Potential vs. Professional Install

Capable DIYers commonly tackle vinyl inserts; step-by-step resources abound. Fiberglass units, being heavier and less forgiving, are best handled by certified pros—some brands tie parts of coverage to professional installation practices.

Noise Reduction & Everyday Comfort (STC/OITC & the Role of Glass)

Quiet comes primarily from glazing: laminated panes, wider airspaces, and triple-pane make the biggest difference. STC/OITC are the metrics to watch; higher numbers mean better noise control. Frame airtightness and operating type (e.g., casement vs. slider) also matter—but the glass package is the star.

Rule of thumb: About +5 STC can feel roughly half as loud to the human ear.

Environmental Impact & Sustainability

Materials, Recyclability & VOCs

PVC production has documented environmental and health concerns, which is why some specifiers scrutinize vinyl content. Fiberglass pultrusions are thermoset composites with long service life and low expansion; embodied impacts vary by resin/glass chemistry and manufacturing. Because end-of-life pathways for all frames are limited, the greenest window is often the one that performs well for decades.

Incentives, Codes & Certifications (ENERGY STAR® & Local Rebates)

Look for the NFRC label and ENERGY STAR certification to verify performance claims. In the U.S., the 25C federal tax credit offers 30% of product cost up to $600 for qualifying windows (ENERGY STAR Most Efficient level). Many utilities also offer cash rebates—use ENERGY STAR’s Rebate Finder for local programs.

Note: Incentive amounts, caps, and qualifying criteria change; confirm current details for your location before purchasing.

When to Choose Vinyl (Best-Fit Scenarios)

You want the lowest upfront cost without sacrificing basic efficiency (choose strong glass packages).

Insert/retrofit replacements where frames are sound and a quick turnaround matters.

You prefer no-paint finishes and simple upkeep.

When to Choose Fiberglass (Best-Fit Scenarios)

Harsh climates (big heat/cold swings) where low expansion helps long-term sealing and stability.

Desire for slimmer sightlines, dark colors, or paintable finishes with a premium look.

Large openings or design loads that benefit from higher stiffness.

Decision Checklist (Room, Climate, Budget, Aesthetics)

Climate target: Match U-factor/SHGC to orientation and zone.

Project type: Insert vs. full-frame/new construction.

Look & feel: Sightlines, color, texture, paintability.

Noise goals: Choose glazing (laminated/triple) for STC/OITC needs.

Budget & incentives: Balance upfront vs. lifetime; check rebates/tax credits.

Ready to compare quotes? Ask two vinyl and two fiberglass vendors to price the same glass package (U-factor/SHGC/AL) so you’re judging apples-to-apples. Bring the NFRC labels to your walkthrough.

Frequent Aluminum Foil Recycling Questions

James Parker

James Parker is an environmental expert, writer, and the founder of Envirose.com. Over the years, he has dedicated his work to studying sustainable practices, renewable energy solutions, and eco-conscious lifestyles. Through Envirose, he aims to inspire individuals to make small yet powerful changes in their daily lives that can collectively create a positive impact on the planet. When he’s not writing or researching, you’ll often find him outdoors, exploring nature and finding new ways to live in harmony with it.